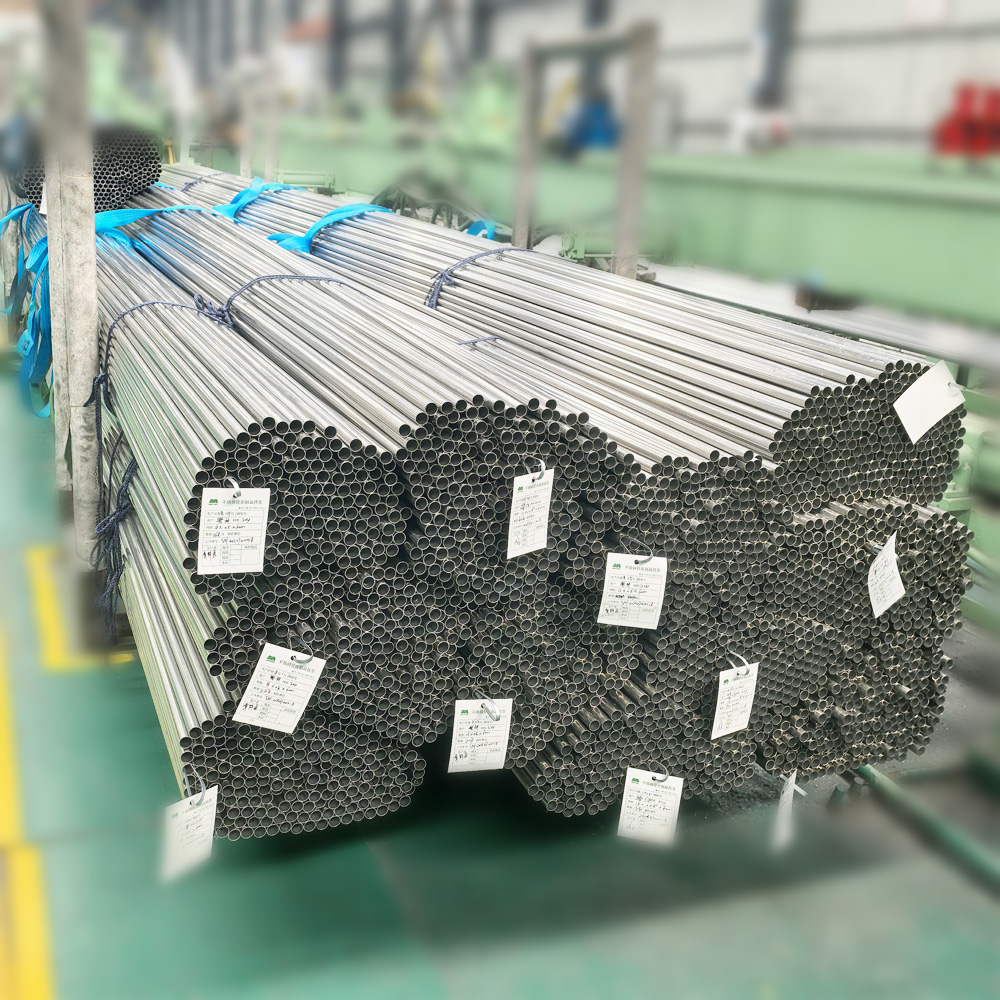

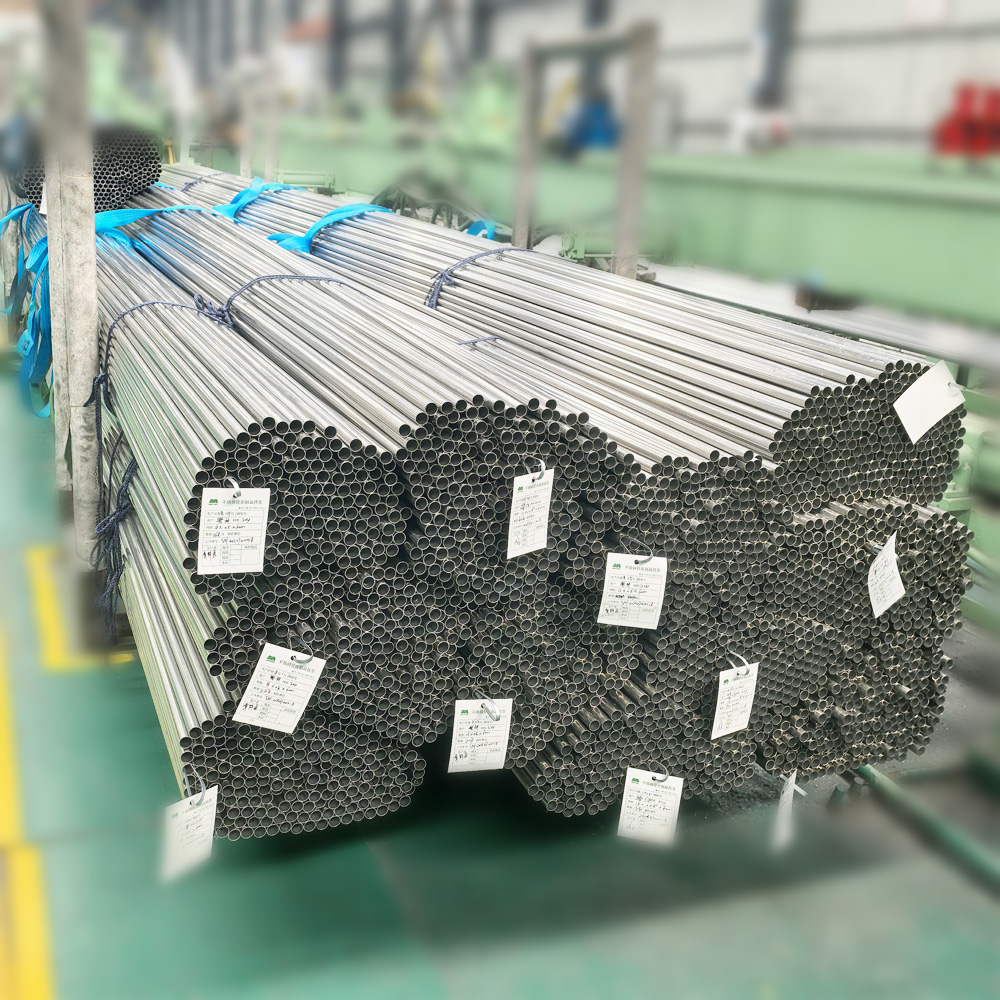

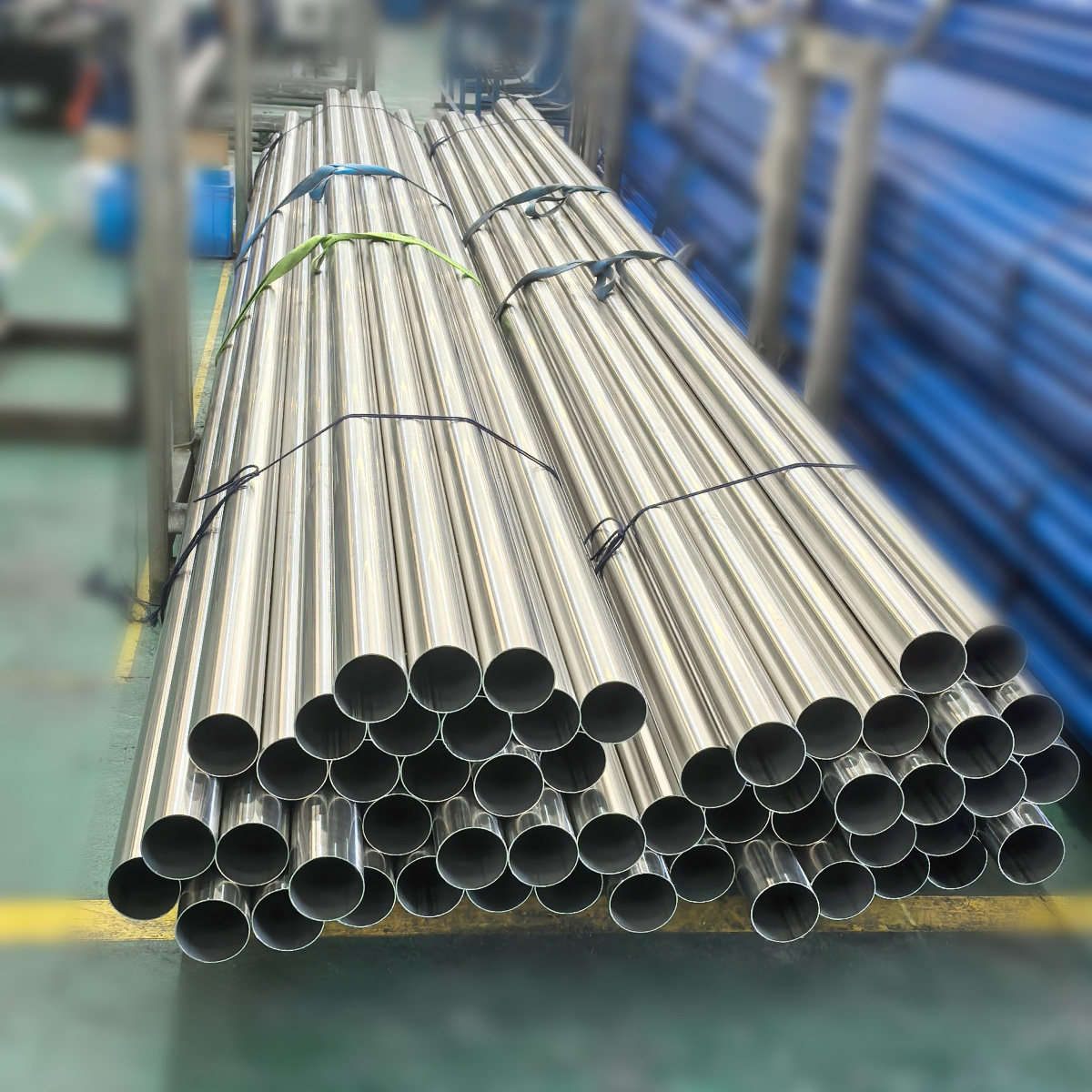

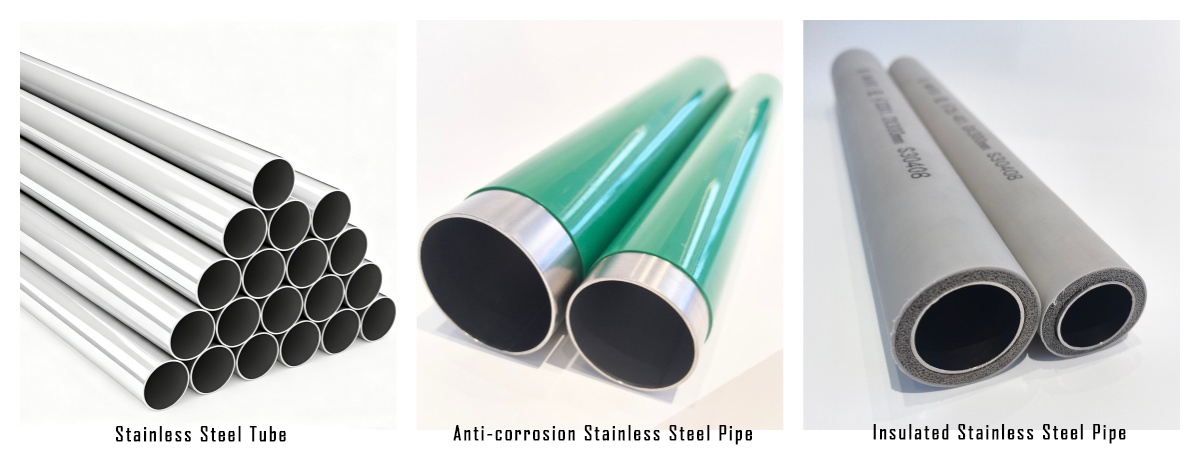

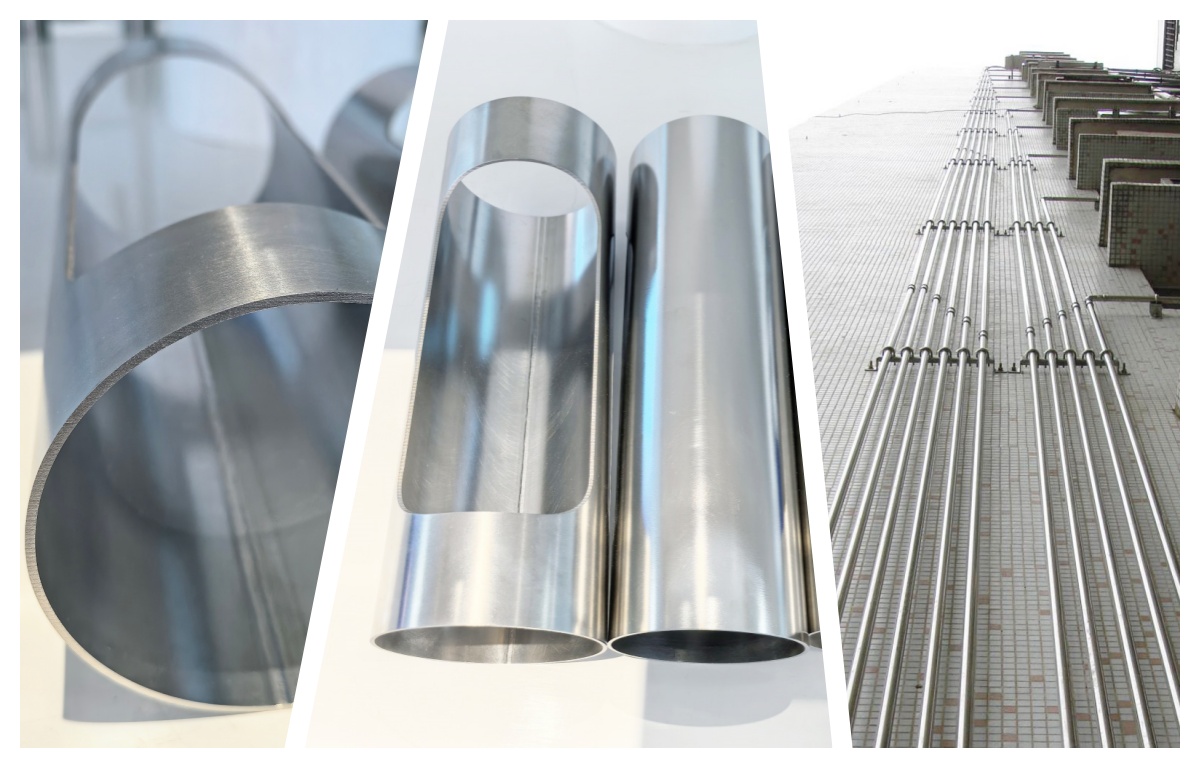

Choose Guangzhou MAYER, and you choose the professional guarantee of nearly 70 years of deep cultivation and the trustworthy quality commitment. Since 1959, we have been dedicated to the R&D and production of sanitary 304/316L stainless steel pipes and fittings, providing core pipeline solutions for safe liquid and gas transportation in multiple industries.

Our products have passed multiple international authoritative certifications such as WaterMark, WRAS, HK WSD, and meet the requirements of Russian GOST standards. Each product undergoes strict quality control, with excellent durability and corrosion resistance, making safe transportation impeccable.

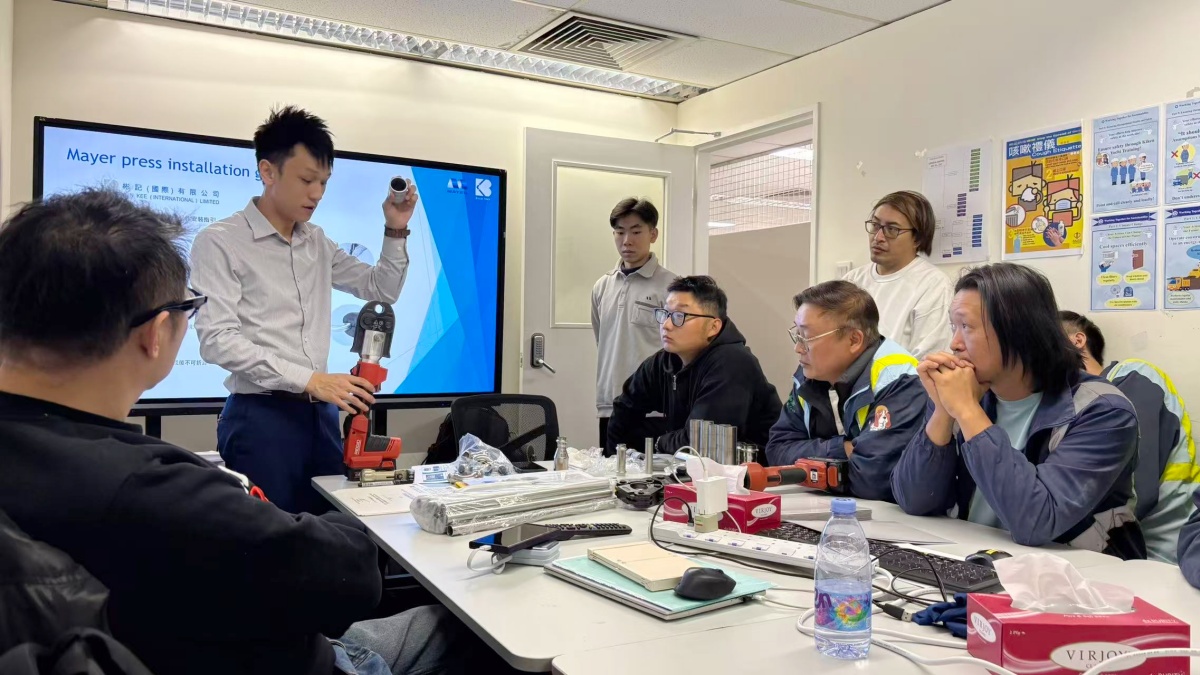

We provide flexible customization of products in various specifications such as GB, JIS, EN, ASTM A312, accurately matching the needs of hospitals, schools, municipal engineering, high-end communities, airports, water utilities and other scenarios. To date, we have accumulated over 5,000 successful cases, winning wide trust from customers in various industries with strength.

Professional accumulation, quality certification, customization capabilities and rich practice together constitute the solid reason for you to choose us.