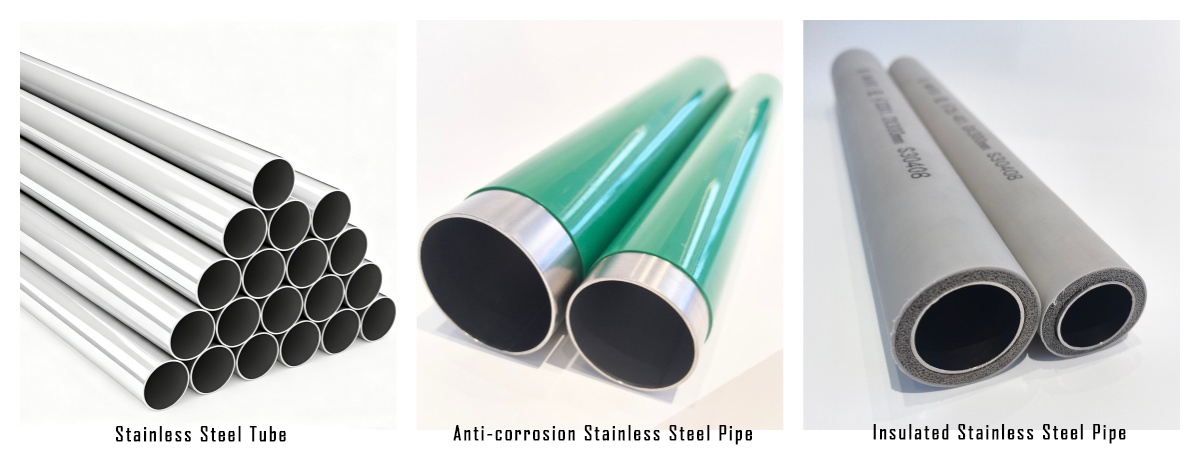

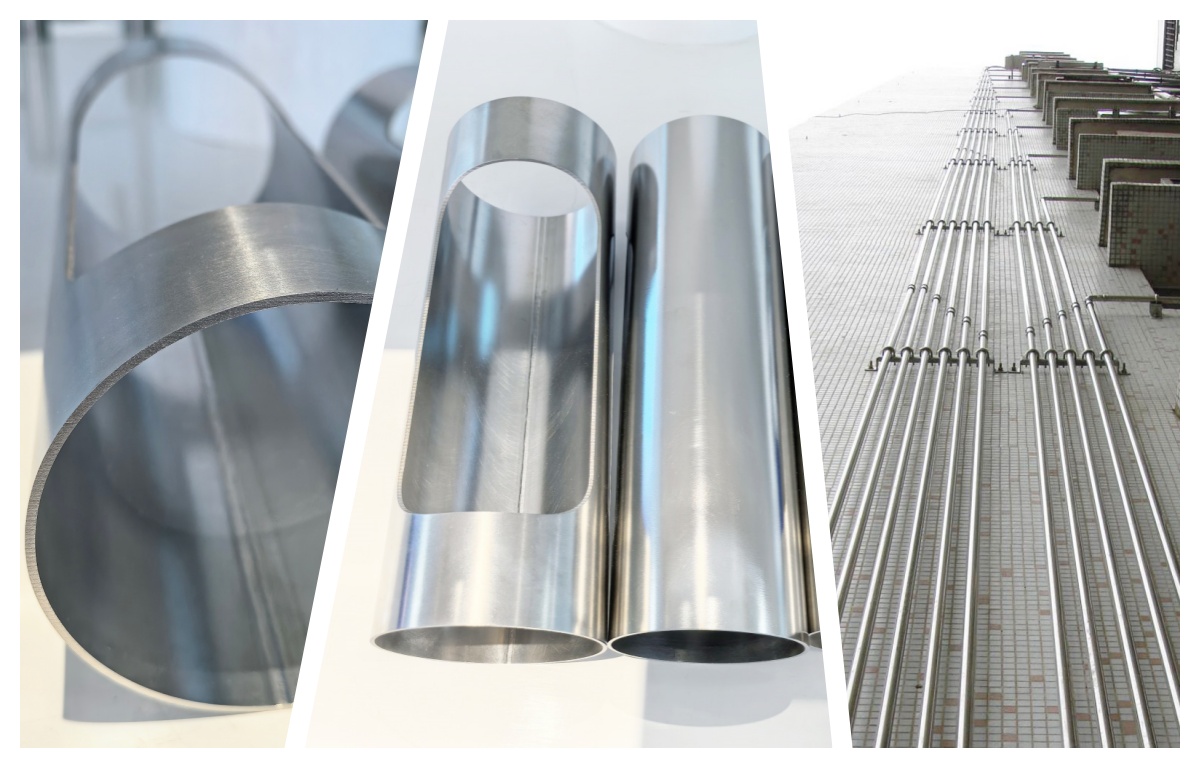

二. Core Reasons for Paper Mills to Select 304/316L Stainless Steel Pipes

1. Excellent corrosion resistance, adapting to the complex corrosive environment of paper mills:

A large number of acid and alkali and oxidizing bleaching agents such as sulfuric acid, sodium hydroxide and sodium hypochlorite are used in the papermaking process, and there are also corrosive impurities such as chloride ions and lignin in the wastewater link.

304 stainless steel has basic acid and alkali corrosion resistance and can meet the transportation needs of conventional process media; 316L stainless steel has a significant improvement in chloride ion corrosion, pitting and crevice corrosion resistance due to the inclusion of molybdenum, which can adapt to strong corrosion processes such as bleaching and wastewater treatment, and fundamentally avoid production interruption caused by pipeline corrosion perforation and leakage.

2. High mechanical strength, adapting to industrial-grade transportation conditions:

304/316L stainless steel pipes have good tensile, compressive and impact resistance, can withstand the high temperature and high pressure of steam transportation and the high-velocity scouring of pulp transportation in paper mills, and the pipelines are not easy to deform and damage, adapting to the continuous and high-load production characteristics of paper mills and ensuring the long-term stable operation of the pipeline system.

3. Good hygiene and anti-scaling, ensuring paper quality and transportation efficiency:

The inner wall of 304/316L stainless steel pipes is smooth with no harmful substances precipitated, which meets industrial hygiene standards and avoids pipeline impurities mixing into the pulp to affect paper quality, especially suitable for the production of high-quality paper such as food packaging paper and household paper; at the same time, the smooth inner wall is not easy to adsorb pulp fibers and impurities, reducing pipeline scaling and blockage, ensuring the flow rate and efficiency of medium transportation, and lowering the frequency of pipeline cleaning and maintenance.

4. Long service life, reducing comprehensive operating costs:

Compared with ordinary carbon steel, galvanized pipes and other pipe materials, 304/316L stainless steel pipes have a significantly extended service life in the corrosive environment of paper mills, reducing the labor and material costs of frequent pipeline replacement; in addition, the wear and corrosion resistance of the pipes greatly reduces the maintenance frequency, which is in line with the production demand of paper mills for cost reduction and efficiency improvement.

5. Strong processability and adaptability, adapting to the complex pipeline layout of paper mills:

304/316L stainless steel pipes can be processed in various ways such as cutting, welding and pipe bending, and can customize pipelines of different specifications and directions according to the workshop layout and equipment supporting needs of paper mills, adapting to the complex installation scenarios of different processes such as pulping and papermaking, and improving the overall adaptability of the pipeline system.