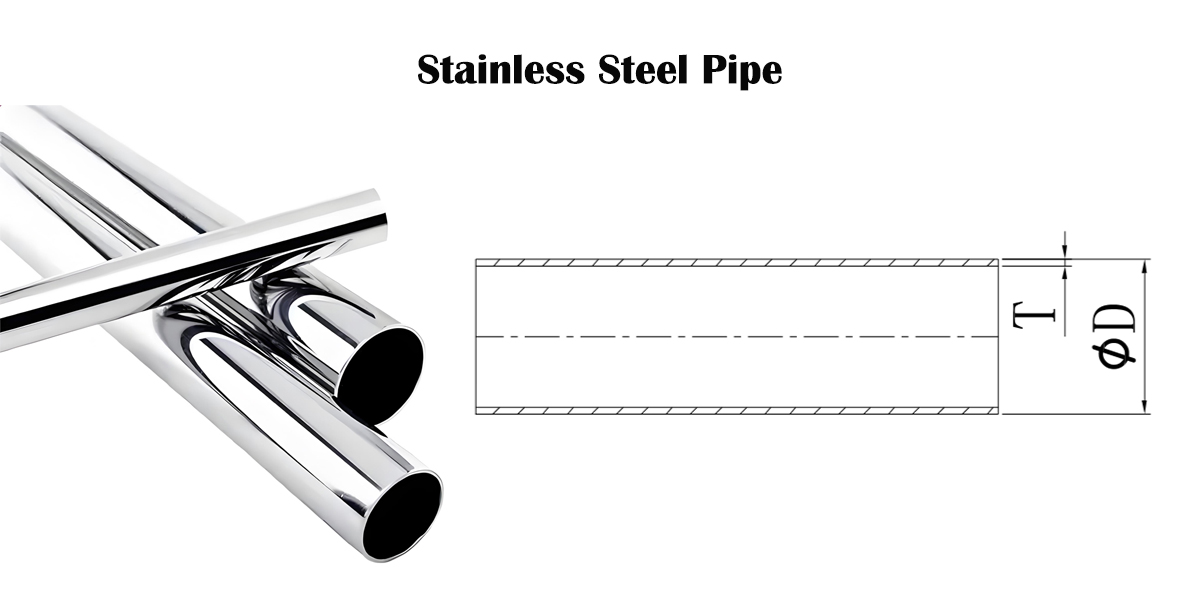

Stainless Steel Tube Use in Chemical and pharmaceutical

In the underground pipelines of chemical parks such as Changshou and Fuling in Chongqing, 304 stainless steel pipes are used for transporting weakly corrosive media such as dilute sulfuric acid and acetic acid, while 316L undertakes the transportation of strongly corrosive media such as hydrochloric acid and high-concentration chloride ion solutions.

In underground chemical environments, pipelines are prone to contact chemical pollutants infiltrated from soil. The chromium-nickel alloy system of 304 can resist conventional corrosion, while 316L has 3-5 times higher corrosion resistance due to the addition of molybdenum, and can operate continuously for 5 years without leakage in the 30% hydrochloric acid transportation scenario.

In addition, both have excellent welding performance, which is not easy to crack due to soil settlement after underground installation, and comply with the GB/T 14976 fluid transportation standard in the chemical industry, avoiding soil pollution caused by medium leakage.

Stainless Steel Tube Use in Petrochemical Field

The working conditions in the petrochemical field are extremely harsh, involving high temperature, high pressure, and various highly corrosive media (such as crude oil, refined oil, acid-base solvents, etc.).

304 stainless steel pipes can be used in auxiliary pipelines under some low-corrosion working conditions, such as ordinary cooling water pipelines and light oil transmission pipelines in oil refineries.

316L stainless steel pipes are one of the core pipeline materials in this field, widely used in oil well casings in crude oil extraction, reaction medium transmission pipelines in chemical plants, liquefied natural gas transmission pipelines, and high-temperature and high-pressure chemical process pipelines.

The core advantage of choosing them is that 304/316L stainless steel pipes have excellent high-temperature and high-pressure resistance and chemical corrosion resistance, which can maintain the sealing and structural integrity of the pipeline under the extreme working conditions of petrochemical production, prevent major safety accidents such as leakage and explosion caused by pipeline failure, and ensure the continuity and safety of production.

Mayer Stainless - Stainless Steel Pipe and Fitting Manufacturer - Inquire Now