Buried stainless steel pipes are used in municipal water supply and direct drinking water projects

In urban water supply networks and old community renovation projects, buried 304 stainless steel pipes are widely used for secondary water supply and conventional drinking water transmission; while in coastal cities and areas along the Yangtze River with high chloride ion concentration, 316L stainless steel pipes are preferred for underground pipelines.

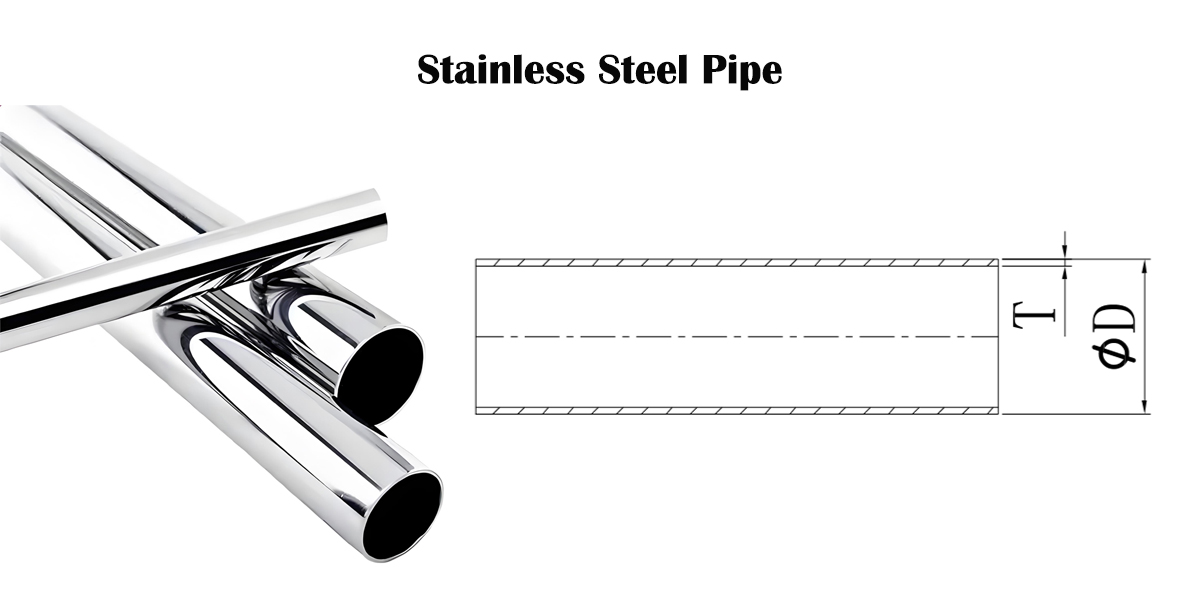

Moisture and trace acid-base substances in underground soil are prone to corrode traditional pipes, causing problems such as "yellow water" and "red water". 304 stainless steel, relying on the dense oxide film formed by chromium, can operate stably for more than 20 years in inland water with chloride ion concentration < 50ppm; 316L, with pitting corrosion resistance enhanced by molybdenum, can withstand the chloride ion environment of 200-500ppm in coastal areas, avoiding corrosion and leakage caused by soil salt spray penetration.

Meanwhile, both meet food contact safety standards, with smooth inner walls that prevent bacterial growth, ensuring water quality safety from the pipe network to the tap. After adopting such pipes in the direct drinking water project in Shenzhen's central urban area, the bacterial count of water decreased from 120CFU/ml to 3CFU/ml.

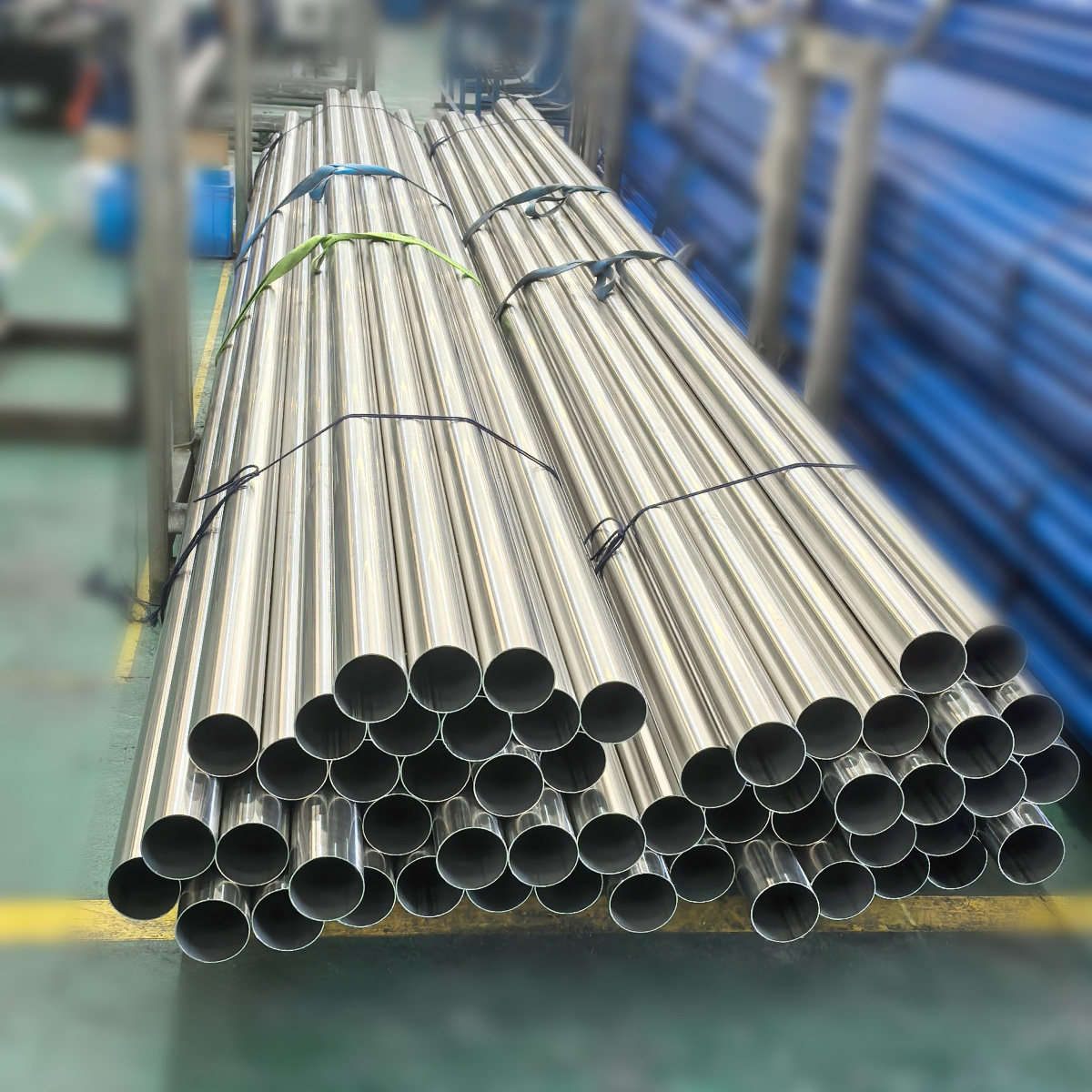

304/316L stainless steel tube for underground water supply

304 stainless steel pipes cover 80% of conventional underground scenarios as the "cost-effective king", suitable for inland low-corrosion projects with limited budgets; 316L conquers 20% of extreme environments as a "corrosion-resistant special soldier", and is irreplaceable in high-chloride, strong-corrosion and high-end demand scenarios. Their common advantages - corrosion resistance, long service life, environmental protection and safety - make them the core solution for underground pipeline projects to get rid of frequent replacement and pollution hazards.

For purchasing stainless steel pipes and fittings, choose Mayer Stainless!

Why choose Mayer? -- Your preferred partner for stainless steel pipes and pipe fittings

When purchasing stainless steel pipes and fittings, why is Mayer the consensus choice in the industry? The answer lies in our more than 20 years of professional accumulation and strong strength.

Founded in 1995, Guangzhou Mayer Corp., Ltd. has developed into a Hong Kong-listed enterprise with a registered capital of 200 million RMB and a workshop area of 55,000 ㎡. As a national high-tech enterprise and a CNAS laboratory certified unit, we not only took the lead in obtaining the three-system certification as early as 1999, but also participated in the compilation of national standards for stainless steel pipes and fittings as an industry leader, defining industry standards with professionalism.

Mayer independently completes the entire process in-house, from raw material incoming, steel coil slitting, to pipe manufacturing and fitting processing, controlling every process from the source. The self-developed ERP system enables precise management and control. Combined with a strict quality inspection system, each finished product is equipped with an exclusive traceability code, which can directly trace back to the raw material source, making quality visible and reliable.

Choosing Mayer means choosing peace of mind and trust.