MAYER - Established in 1995, a professional manufacturer of stainless steel pipes and fittings

MAYER - Established in 1995, a professional manufacturer of stainless steel pipes and fittings

MAYER Stainless Steel Tube Workshop

Stainless Steel Fitting M Profile

Stainless Steel Grooved Fittings

| 304/316L Stainless Steel Fitting Manufacturer Wholesale |

| Product Name |

304/316L Sanitary Stainless Steel Fitting |

| Material |

SUS304, SUS316L |

| Standard |

GB, JIS, EN, ASTM A312 |

| Certificate |

WaterMark, WRAS, HK WSD,and have also passed testing for compliance with Russian GOST requirements |

| Size |

DN65 |

| DN80 |

| DN100 |

| DN125 |

| DN150 |

| DN200 |

| DN250 |

| DN300 |

| Customize |

YES |

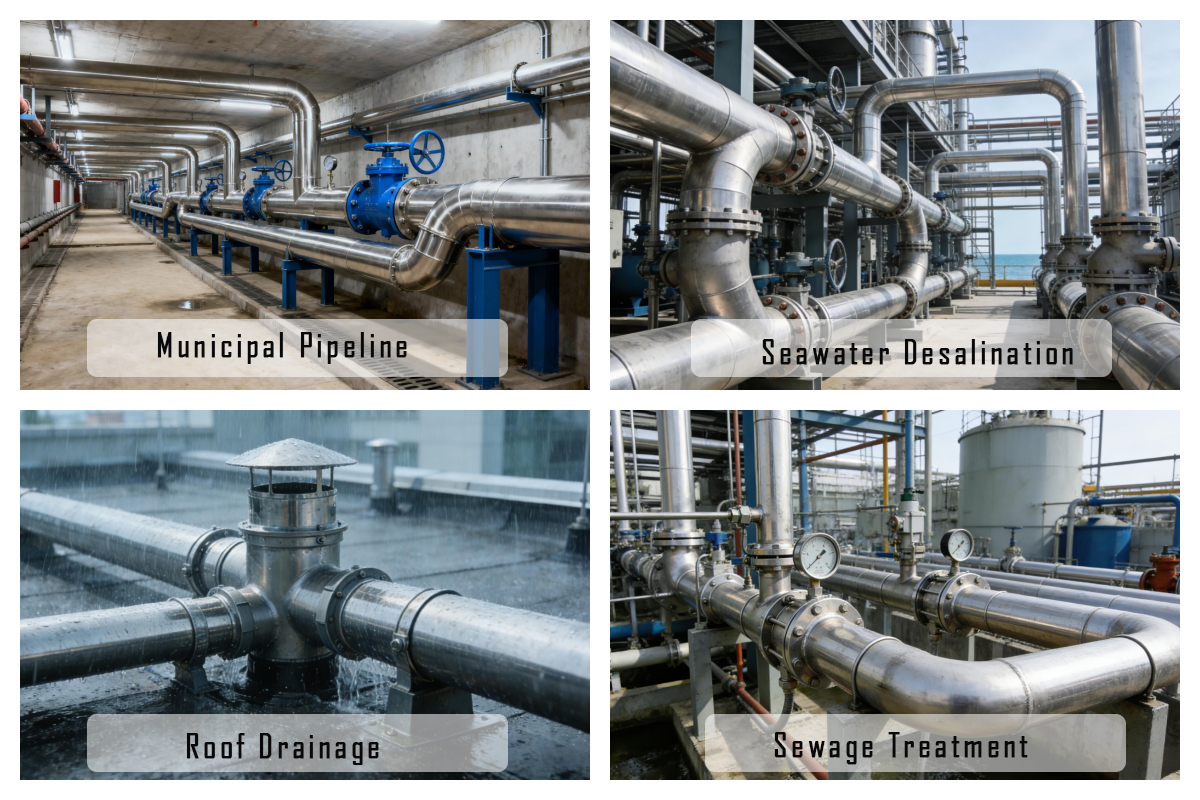

Application of stainless steel pipe fittings

Applications and Selection Advantages of 304/316L Stainless Steel Pipes and Fittings in Municipal Fields

I. Municipal Application Scenarios

1. 304 Stainless Steel Pipes and Fittings

• Municipal water supply projects: Water supply networks in inland cities, secondary water supply pipes and fittings in residential communities, suitable for mild corrosive environments such as fresh water.

• Conventional gas transmission: Low-pressure natural gas transmission branch pipes in cities, meeting the requirements of normal pressure and temperature working conditions.

• Municipal heating systems: Hot water transmission pipes for urban central heating, with stable oxidation resistance below 800℃.

• Ordinary municipal drainage: Rainwater and domestic sewage discharge pipes without strong corrosive media.

304 Stainless Steel Pipe and Fitting for Water Supply

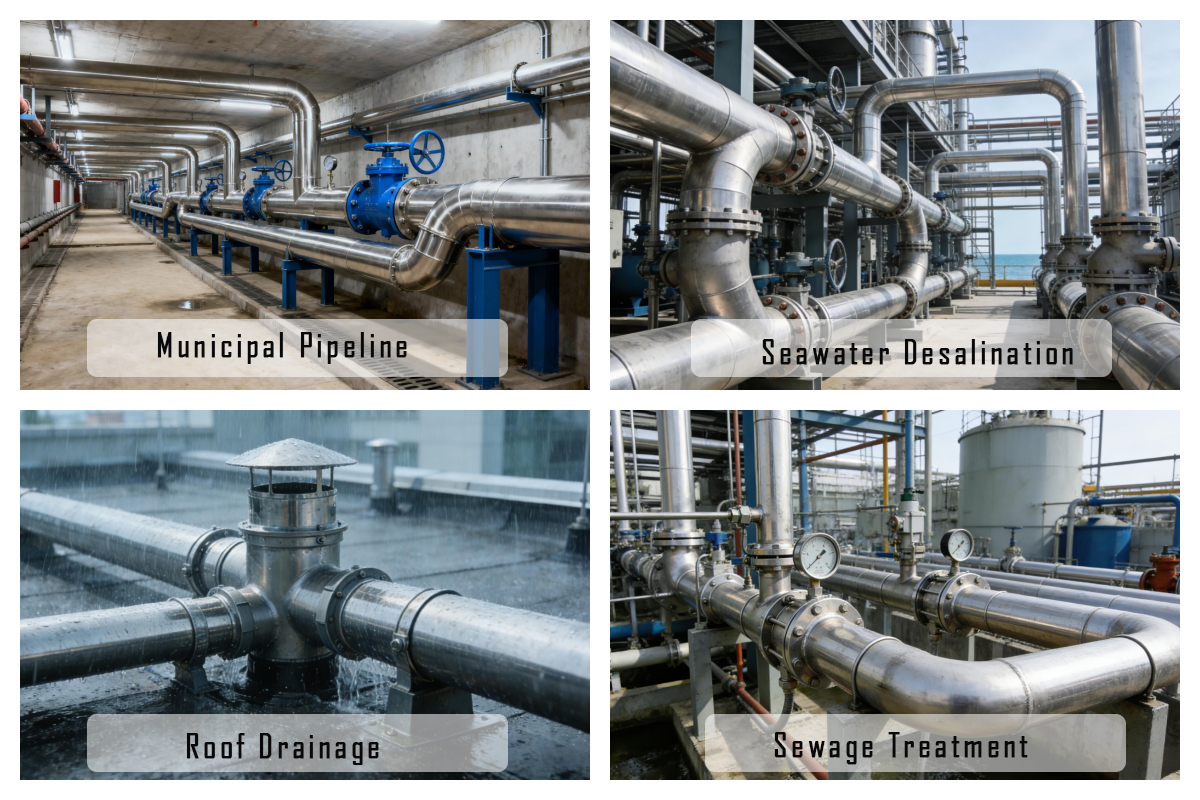

2. 316L Stainless Steel Pipes and Fittings

• Coastal municipal projects: Water supply networks in coastal cities, municipal pipes in salt spray areas, with chloride ion corrosion resistance 3-5 times that of 304.

• Sewage treatment systems: Pipes and fittings for transporting chlorine-containing wastewater and acid-alkali sewage, resistant to various corrosive media.

• High-end municipal supporting facilities: Direct drinking water projects, water supply pipes supporting large-scale events/summits, meeting hygienic standards.

• Special gas transmission: Branch lines of high-pressure natural gas long-distance transmission pipelines, adapting to anti-static and corrosion resistance requirements.

316L stainless steel pipes and fittings are used for wastewater treatment or seawater desalination

II. Core Reasons for Selection

1. Excellent corrosion resistance:

304 forms a dense oxide film with 18Cr-8Ni composition, suitable for conventional mild municipal environments; 316L adds 2%-3% molybdenum, resisting harsh corrosion such as seawater, salt spray, acid and alkali, greatly reducing pipeline leakage risks.

2. Hygienic and environmental protection:

Non-toxic and bacteriostatic, smooth inner wall not easy to breed bacteria, meeting drinking water hygiene standards, no heavy metal precipitation, ensuring municipal water supply safety.

3. Ultra-long service life:

304 has a service life of more than 50 years, and 316L can reach 70-100 years, far exceeding traditional galvanized pipes and plastic pipes, reducing the cost of repeated reconstruction of municipal pipe networks.

4. Convenient installation and maintenance:

Press-connect technology can be adopted, improving construction efficiency by 50% with low later maintenance cost; excellent material toughness, adapting to complex municipal working conditions such as geological subsidence.

5. Precise adaptation to cost:

304 has high cost performance, suitable for conventional municipal scenarios; although 316L costs 20%-40% higher, it can avoid frequent replacement in harsh environments, achieving optimal life-cycle cost.

Stainless Steel Tube and Fitting Easy Installation

Our Certificate

Why Choose Us?

Established in 1595, Guangzhou MAYER is specialized in hygienic 304/316L stainless steel pipes and fittings, offering safe and stable fluid & gas transmission pipelines for various industries.

Our products hold WaterMark, WRAS, HK WSD and other international certifications, and pass the tests meeting Russian GOST requirements with guaranteed quality.

We support customization of GB, JIS, EN, ASTM A312 specifications, and supply durable, corrosion-resistant solutions under strict quality control. With over 5000 successful cases in hospitals, schools, municipal works, high-end communities, airports and water sectors, we are your reliable partner.