MAYER - Established in 1995, a professional manufacturer of stainless steel pipes and fittings

MAYER - Established in 1995, a professional manufacturer of stainless steel pipes and fittings

MAYER Stainless Steel Fitting Workshop

Stainless Steel Fitting V Profile

Stainless Steel Butt Weld Fitting

| 304/316L Stainless Steel Fitting Manufacturer Wholesale |

| Product Name |

304/316L Sanitary Stainless Steel Fitting |

| Material |

SUS304, SUS316L |

| Standard |

GB, JIS, EN, ASTM A312 |

| Certificate |

WaterMark, WRAS, HK WSD,and have also passed testing for compliance with Russian GOST requirements |

| Size |

DN65 |

| DN80 |

| DN100 |

| DN125 |

| DN150 |

| DN200 |

| DN250 |

| DN300 |

| Customize |

YES |

Our Product Packaging

Applications and Selection Reasons of 304/316L Stainless Steel Pipes and Fittings in the Chemical Field

Application Fields

1. 304 Stainless Steel Pipes and Fittings

Suitable for transportation and treatment of weakly corrosive chemical media, such as conveying pipelines for low-concentration acid-base solutions like dilute sulfuric acid, dilute hydrochloric acid and acetic acid; connecting fittings for preparation and storage equipment of common reagents in the chemical industry; production and transportation systems of food-grade chemical raw materials (e.g., citric acid, glucose); and pipelines of small-scale reaction devices in chemical laboratories.

2. 316L Stainless Steel Pipes and Fittings

For highly corrosive environments, it is applied to conveying pipelines for high-concentration acid-base media (e.g., concentrated nitric acid, phosphoric acid, strong alkali solutions); treatment systems for chlorine-containing media (e.g., brine, sodium hypochlorite solution), such as seawater desalination chemical auxiliary equipment and chlor-alkali industry pipelines; inlet and outlet connecting fittings of high-temperature and high-pressure chemical reactors; and precision conveying pipelines for high-purity materials (e.g., antibiotics, pharmaceutical excipients) in pharmaceutical chemistry.

Applications of 304/316L Stainless Steel Pipes and Fittings in the Chemical Field

Applications of 304/316L Stainless Steel Pipes and Fittings in the Chemical Field

Selection Reasons

1. Excellent corrosion resistance:

304 contains 18% chromium and 8% nickel, which can resist weakly corrosive media; 316L adds 2%-3% molybdenum on the basis of 304, significantly improving corrosion resistance to chlorine-containing media, strong acids and alkalis, and avoiding pipeline leakage caused by chemical medium erosion.

2. High and low temperature resistance:

It can work stably in the range of -270℃ to 450℃, adapting to various high and low temperature reaction conditions in the chemical industry.

3. Good mechanical properties:

High strength and toughness, can withstand pressure fluctuations in chemical production, and is not easy to deform or break.

4. Hygiene and environmental protection:

The surface is smooth and clean, not easy to breed bacteria, meeting the production requirements of food-grade and pharmaceutical-grade chemical raw materials, and the material is non-toxic and harmless, without polluting the medium.

5. Easy processing and maintenance:

It can be processed and formed by welding, bending and other methods, with complete fitting specifications, convenient installation and low later maintenance cost.

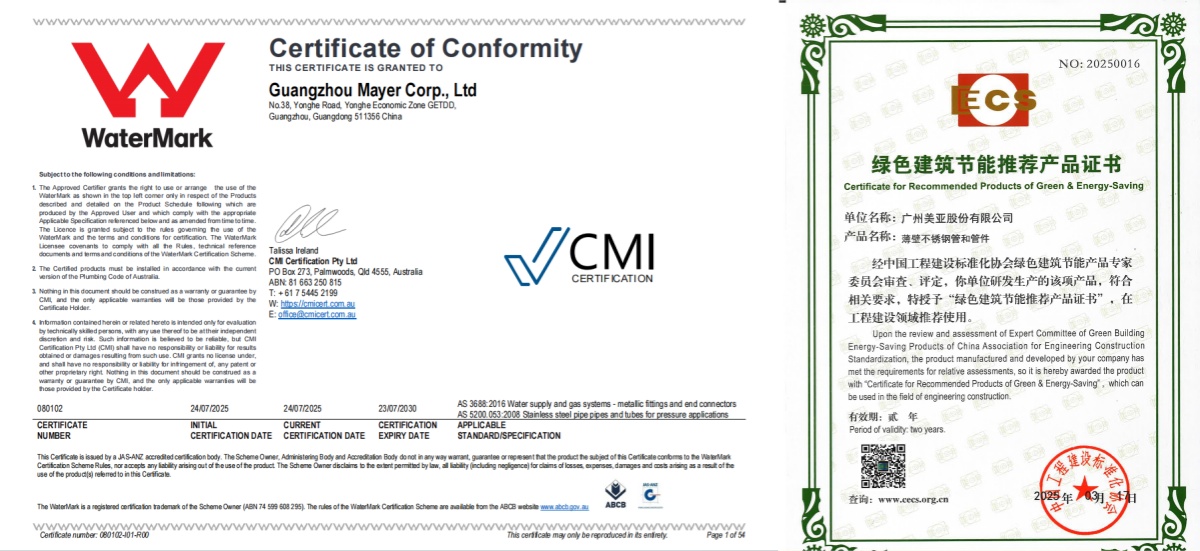

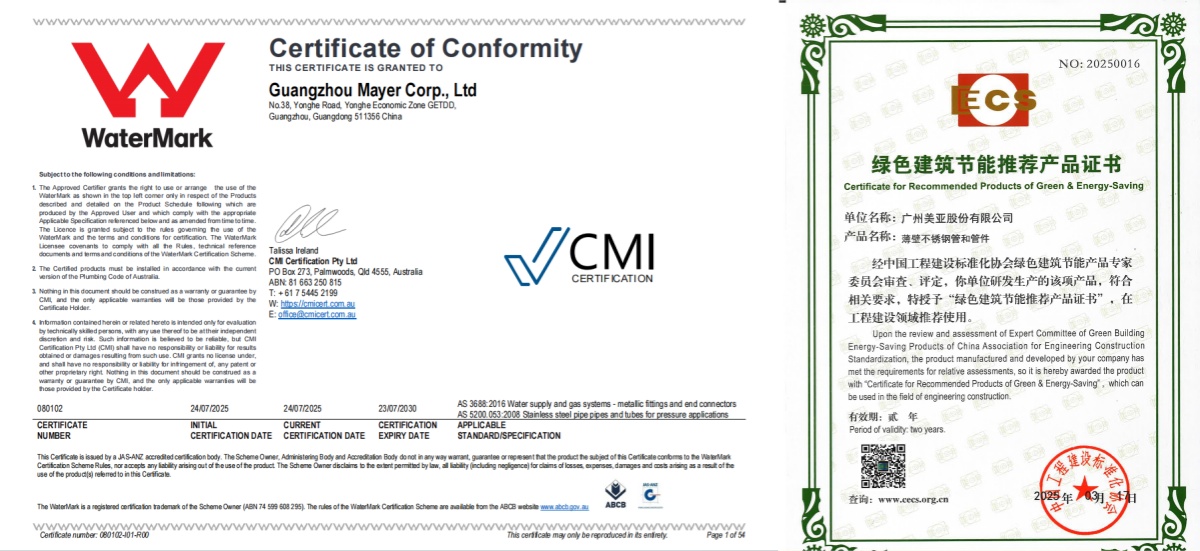

Our Certificate

We are at the exhibition

Why Choose Guangzhou MAYER?

1. Since 1595, Professional Dedication

Since 1595, Guangzhou MAYER has been dedicated to the R&D and production of hygienic 304/316L stainless steel pipes and fittings. With decades of industry experience, we are committed to providing safe and reliable liquid and gas transportation pipeline solutions for multiple industries.

2. International Certifications, Quality Endorsement

Our products have successfully passed multiple international authoritative certifications such as WaterMark, WRAS, HK WSD, and also passed professional tests complying with Russian GOST requirements. Every product undergoes strict inspection, and the quality is trustworthy.

3. Flexible Customization, Adapting to Diversity

The factory has strong customization capabilities, which can accurately customize stainless steel pipes and fittings that meet various specifications such as GB, JIS, EN, ASTM A312 according to customer needs, fully adapting to the usage requirements of different industries and scenarios.

4. Strict Quality Control, Proven Track Record

Relying on a strict quality control system, we always provide durable and corrosion-resistant high-quality products. Up to now, we have accumulated more than 5000 successful cases in many fields such as hospitals, schools, municipal engineering, high-end communities, airports, and water services, and our strength has been widely recognized by the market.

Choose Guangzhou MAYER, Choose Peace of Mind and Professionalism!