E-mail : info@mayer.cn

E-mail : info@mayer.cn

2022-09-26

Why is stainless steel "magnetic"?

Don't judge the quality and authenticity of stainless steel products by whether they are magnetic. Today, let's learn about stainless steel magnetism!

According to the research of material physics, the magnetism of metal comes from the structure of electron spin, which belongs to quantum mechanical properties, and can be "up" or "down".In ferromagnetic metals, electrons will automatically spin in the same direction, while in antiferromagnetic metal materials, some electrons will spin in a regular mode, while adjacent electrons will spin in the opposite direction or anti parallel. However, for electrons in a triangular lattice, since two electrons in each triangle must spin in the same direction, the spin structure no longer exists.

Why is "magnetism" sometimes absent?

Generally speaking, austenitic stainless steel (represented by 304) is nonmagnetic, but it may also have weak magnetism, while ferrite (mainly 430, 409L, 439, 445NF, etc.) and martensite (represented by 410) are generally magnetic. In stainless steel, some steel grades (such as 304) are classified as "non-magnetic stainless steel", which means that its magnetic index is lower than a certain value, that is, generally stainless steel is more or less magnetic. In addition, it is mentioned above that austenite is non-magnetic or weak magnetic, while ferrite and martensite are magnetic. Due to component segregation or improper heat treatment during smelting, a small amount of martensite or ferrite structure will appear in austenitic 304 stainless steel, so weak magnetism will appear in 304 stainless steel. In addition, after cold working, the structure of 304 stainless steel will also transform to martensite. The larger the cold working deformation is, the more martensite transformation is, and the stronger the magnetism will be. If you want to completely eliminate the magnetism of 304 stainless steel, you can restore and stabilize the austenite structure through high temperature solution treatment, so as to eliminate the magnetism. The aging treatment can also be used to eliminate the stress caused by the cold working deformation of the material (which will also affect the direction of electron rotation and produce magnetism), so as to weaken the magnetism (aging treatment cannot completely eliminate the stress). Therefore, the magnetism of materials is determined by whether the molecular arrangement is regular and the electron spin is in the same direction. It is the physical properties of materials, while the corrosion resistance of materials is determined by the chemical composition of materials, which is the chemical properties of materials, regardless of whether the materials have magnetism.

Whether there is "magnetism" has nothing to do with the quality of the product.

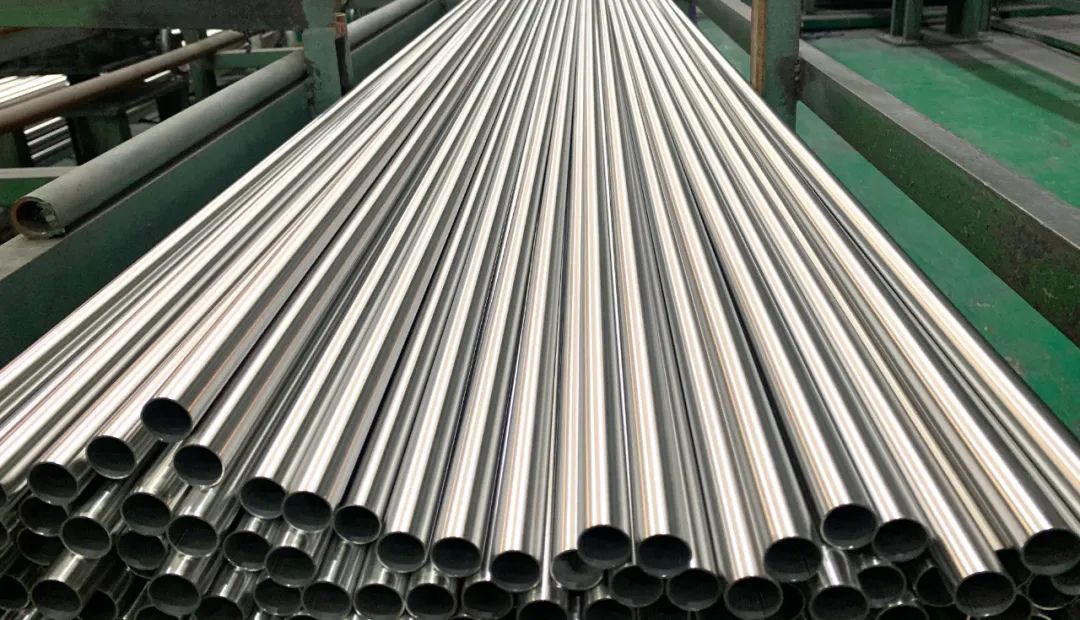

People often think that magnets absorb stainless steel to verify its advantages and disadvantages and authenticity. They do not absorb non-magnetic materials, and they think it is good and genuine; If the sucker is magnetic, it is considered to be a fake. In fact, this is a one-sided and inaccurate identification method. After cold working, the structure of 304 stainless steel will also transform to martensite. The greater the cold working deformation, the more martensite transformation, and the greater the magnetic properties of the steel. Production of steel strip of the same batch number Φ 76 tubes, no obvious magnetic induction, production Φ 9.5 Pipe. As the cold bending deformation is large, the magnetic induction is obvious. As the deformation of square and rectangular pipes is larger than that of round pipes, especially in the corner section, the deformation is more intense and the magnetism is more obvious.

SUS304 will produce weak magnetism after cold rolling deformation, welding, cutting and other processing, while the magnetism can be basically eliminated through solid melting treatment; The existing magnetism will gradually weaken after being stacked in the open air for a certain period of time (equivalent to aging treatment). Aging treatment: refers to the heat treatment process in which the properties, shape and size of alloy workpieces change with time when they are placed at a higher temperature or kept at room temperature after solution treatment, cold plastic deformation or casting.

The forming of pipe fittings of Guangzhou Mayer belongs to cold processing deformation, and there is weak magnetism after processing. Although the weak magnetism of most pipe fittings is basically eliminated after solid melting treatment, some pipe fittings may still have weak magnetism (relatively speaking), which can be reflected when being absorbed by magnets, which is a normal phenomenon.