E-mail : info@mayer.cn

E-mail : info@mayer.cn

2025-07-08

In modern society, stainless steel pipes are widely used in various fields due to their corrosion resistance and high strength. However, despite both being called "stainless steel pipes," those designed for industrial use differ significantly from those intended for drinking water systems. This article explains the key distinctions between these two types of pipes in simple, easy-to-understand terms.

1. Different Material Standards

Industrial stainless steel pipes typically use 304 or 316 stainless steel, which offer good corrosion resistance and mechanical strength, suitable for most industrial environments.

Drinking water stainless steel pipes, however,

must use food-grade stainless steel, commonly 304 (06Cr19Ni10) or 316L (022Cr17Ni12Mo2) in China. These materials have strict limits on heavy metal content.

Food-grade stainless steel must control harmful elements such as lead and cadmium during production. According to China’s GB 4806.9-2016 standard (National Food Safety Standard for Metal Materials and Products in Food Contact), lead content must be ≤0.01 mg/dm², and cadmium content must be ≤0.005 mg/dm². Industrial pipes have no such strict requirements.

2. Differences in Manufacturing Processes

Industrial stainless steel pipes have relatively simple production processes, focusing mainly on mechanical strength and corrosion resistance.

Drinking water pipes, however, require more precise manufacturing controls:

1)Internal Surface Treatment – Drinking water pipes must have an extremely smooth interior (Ra ≤ 0.8 μm) to prevent scale buildup and bacterial growth. Common treatments include mechanical polishing, electrolytic polishing, or passivation.

2)Welding Technology – High-quality drinking water pipes use TIG welding (argon arc welding) with internal gas protection to ensure smooth, oxide-free welds. Some premium pipes even use laser welding.

3)Cleanliness Control – Production must avoid contamination from oils, dust, or other pollutants. Pipes undergo strict cleaning and testing before leaving the factory.

3. Different Hygiene Certifications

Drinking water stainless steel pipes must meet strict health and safety certifications, such as:

China’s "Hygienic License for Products Related to Drinking Water Safety"

Compliance with GB/T 17219-1998 (Safety Evaluation Standard for Drinking Water Transmission and Distribution Equipment)

International certifications like NSF/ANSI 61 (U.S.) or KTW (Germany) for high-end products

Industrial pipes, on the other hand, focus on pressure certifications (e.g., GB/T 20801) and mechanical performance, with no hygiene requirements.

4. Different Applications & Performance Focus

Industrial Stainless Steel Pipes:

Used in chemical, petroleum, and pharmaceutical industries for fluid transport

Emphasize high pressure resistance, high-temperature tolerance, and corrosion resistance

Operating temperature range: -196°C to 800°C

Allow minimal metal ion leaching

Drinking Water Stainless Steel Pipes:

Designed for potable water systems in homes, schools, hospitals, etc.

Prioritize hygiene and water safety

Operating temperature range: 0°C to 100°C

Require extremely low metal ion leaching to avoid affecting water taste

5. Price & Lifespan Differences

Due to material and process differences, drinking water stainless steel pipes cost 20%-50% more than industrial pipes of the same specifications. However, they offer long-term benefits:

High-quality drinking water pipes can last 50-70 years

Industrial pipes in corrosive environments may need replacement every 10-20 years

Lower maintenance costs for drinking water pipes (no frequent cleaning required)

Buying Tips:

Know the Purpose – Never use industrial pipes for drinking water systems to avoid health risks.

Check Certifications – Legitimate drinking water pipes should have "food-grade" markings and hygiene approval

Inspect Quality – High-quality pipes have mirror-smooth interiors, uniform welds, and no odors.

Brand selection:

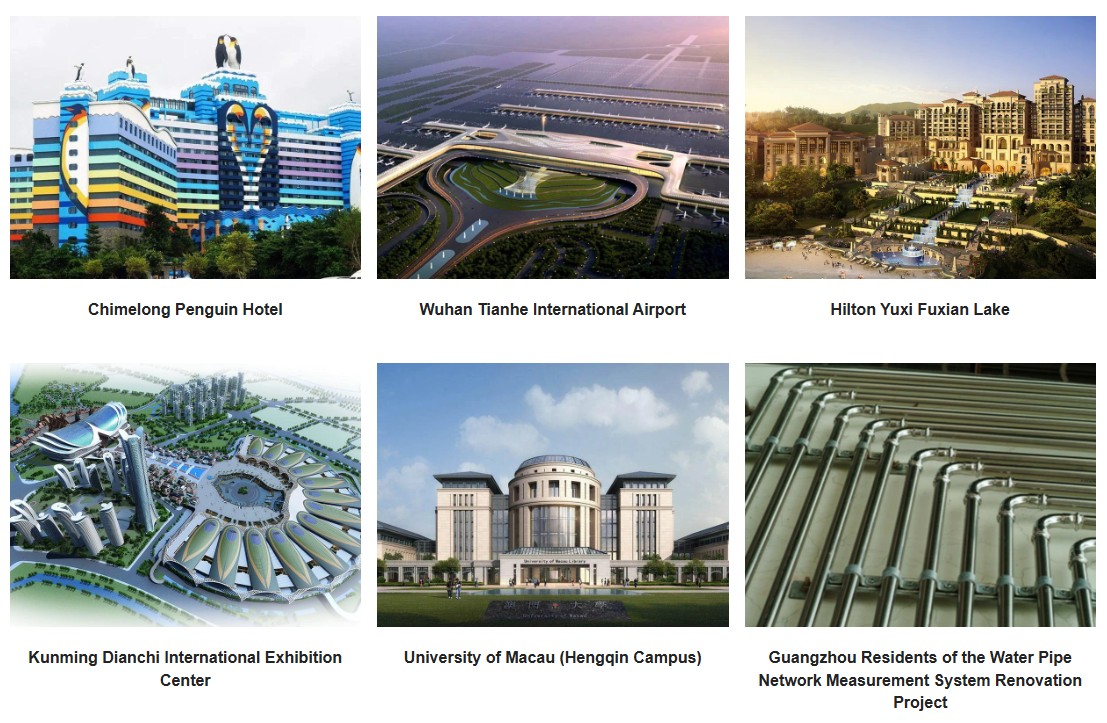

Guangzhou Mayer is a professional enterprise that produces stainless steel drinking water pipes. It was established in 1995 and has 30 years of experience in producing stainless steel water pipes.

Mayer uses food grade 304 and 316L stainless steel materials, and focuses on the hygiene and safety of stainless steel water pipes during the production process;

The pipe wall is smooth and free of dirt (not easy to breed bacteria), and the water flow rate is fast;

Service life>70 years; Resistance to water flow impact>2.5M Pa;

Explosion proof, fire-resistant, and shockproof;

Adopting dual card compression technology, leak proof and quick installation.

Final Thoughts:

As people become more health-conscious, stainless steel pipes are increasingly replacing traditional galvanized steel and PPR pipes in drinking water systems. Understanding the differences between industrial and drinking water pipes helps ensure safe, cost-effective choices for different applications.

Key Rule: Any pipe that comes into contact with drinking water must use food-grade stainless steel to ensure safety.