E-mail : info@mayer.cn

E-mail : info@mayer.cn

2022-10-27

Many users will have such a question, is the seal ring of the stainless steel water pipe connected by the clamp type reliable? Will the pipeline leak due to its inelasticity after aging? Is the material safe? Will harmful substances be released? Today we will learn about sealing materials!

Ring compression type and clamp compression type connections use the effective rigidity of the material itself as the inner wall support, use the clamp tools to crimp the pipe fittings and pipes, and use the sealing materials to seal the connection. The service life of crimp type pipes is generally determined by the service life of sealing materials.

The internationally recognized sealing rule is to use the principle of material compression ratio for sealing, and the compression ratio of compression fitting connection is generally between 20% - 30%. "Line" seal is the most basic principle of O-ring, which is much more reliable than "face" seal. The standard test for measuring the compression ratio of sealing materials is the compression permanent deformation test in water in the national standard GB/T19228.3 (70 days, 110 degrees, and the compression loss should be less than 30%). O-ring is internationally recognized as a sealing material with superior compression ratio.

It is understood that the international choice of sealing materials is generally chlorinated butyl and ethylene propylene diene monomer. These two materials not only meet the hygienic performance standards, but also have excellent elastic compression performance and strength up to GB/T19228.3 standard. During the use of water pipes, water pressure and vibration have high requirements on the tensile strength of sealing materials. The fracture of sealing materials is one of the main factors for water leakage of water pipes.

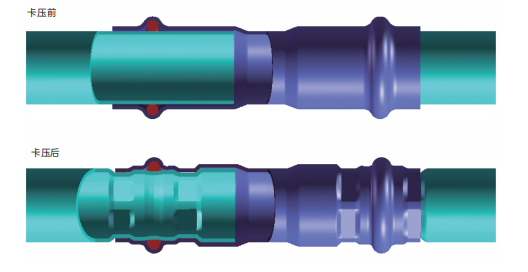

Mayer double clamping thin-walled stainless steel pipe is connected by using hydraulic pliers to compress, and the pipe ends produce concentric contraction to play a role in sealing. The crimping position of pipes and pipe fittings changes hexagonal shape to improve the anti pulling effect. The compression ratio principle of O-ring seal is adopted to exert its long-term elasticity after the compression of U-groove O-ring seal, so as to achieve the purpose of sealing.