In the food and beverage (F&B) industry, hygiene, safety, and compliance are non-negotiable. Every component of your processing system—especially stainless steel pipes and fittings — plays a critical role in preventing contamination, ensuring product quality, and meeting strict global standards. As a trusted manufacturer of stainless steel pipes and fittings, we’ve compiled this comprehensive guide to address the questions our F&B clients (processors, plant managers, engineers, and procurement teams) ask most frequently. Whether you’re upgrading your existing system, building a new facility, or sourcing reliable food-grade stainless steel components, this guide will help you make informed decisions— and understand why high-quality stainless steel is the backbone of safe food and beverage production.

Why Stainless Steel Is the Gold Standard for Food & Beverage Processing?

When it comes to F&B processing, stainless steel isn’t just a choice—it’s a requirement. Unlike other materials (such as carbon steel, plastic, or copper), stainless steel offers unique properties that align perfectly with the industry’s strict demands, making it the ideal material for stainless steel pipes and fittings.

• Hygienic & Non-Porous: stainless steel has a smooth, non-porous surface that prevents the growth of bacteria, mold, and other harmful microorganisms. This is critical for stainless steel pipes and fittings used in F&B processing, as it avoids cross-contamination between batches and ensures food safety.

• Corrosion Resistance: F&B processing involves acids (e.g., fruit juices), salts (e.g., sauces), high temperatures, and frequent cleaning with harsh sanitizers (e.g., chlorine). stainless steel resists corrosion from these substances, maintaining the structural integrity of stainless steel pipes and fittings and preventing metal leaching into products.

• Easy to Clean & Sanitize: The smooth polish of sanitary stainless steel pipes and fittings allows for thorough cleaning (manual or CIP—Clean-in-Place systems) and sanitization, reducing downtime and ensuring compliance with hygiene standards for F&B processing.

• Durability & Longevity: stainless steel pipes and fittings have a long service life, even in high-pressure, high-temperature F&B environments. This reduces replacement costs and minimizes production disruptions for F&B facilities.

• Food-Grade Compliance: food-grade stainless steel meets global standards (e.g., FDA, 3A, CE) that confirm it is safe for direct or indirect contact with food and beverages, making it suitable for manufacturing stainless steel pipes and fittings.

Key Material Selection for Food & Beverage Stainless Steel Pipes & Fittings

Not all stainless steel is suitable for F&B processing. The two most common grades used in manufacturing stainless steel pipes and fittings are Grade 304 Stainless Steel and Grade 316L Stainless Steel — but choosing the right one depends on your specific application. Below is a clear comparison to help you select the best option for your stainless steel pipes and fittings.

1. Grade 304 Stainless Steel

Grade 304 Stainless Steel is the most widely used stainless steel grade in the F&B industry, thanks to its balance of performance and cost-effectiveness. It contains 18% chromium and 8% nickel, offering excellent corrosion resistance to mild acids, water, and most food products—making it ideal for producing stainless steel pipes and fittings of Grade 304.

Best for: Standard F&B applications such as water supply, dairy processing (milk, yogurt), bakery, confectionery, and non-acidic beverages (e.g., water, tea, coffee). It is also ideal for applications where sanitization is frequent but not overly aggressive, suitable for stainless steel pipes and fittings of Grade 304.

2. Grade 316L Stainless Steel

Grade 316L Stainless Steel is a “superior” food-grade stainless steel, with the addition of molybdenum (2-3%)—a component that enhances corrosion resistance, especially against harsh chemicals and acidic environments. The “L” indicates low carbon content, which prevents sensitization (corrosion at the grain boundaries) during welding—making it perfect for stainless steel pipes and fittings of Grade 316L.

Best for: Aggressive F&B applications such as acidic fruit juices (orange, lemon), tomato products, pickles, sauces (soy, Worcestershire), seafood processing, and any system cleaned with strong sanitizers (e.g., peracetic acid). It is also required for high-hygiene environments like craft breweries and wineries, where stainless steel pipes and fittings of Grade 316L are essential.

| Pro Tip: If you’re unsure which grade to choose for your stainless steel pipes and fittings, ask yourself: Does my product contain acids, salts, or sulfites? Will my system be cleaned with aggressive sanitizers? If yes, Grade 316L Stainless Steel is the safer choice. For standard applications, Grade 304 Stainless Steel offers excellent value. |

Essential Types of Sanitary Stainless Steel Pipes & Fittings for F&B

Food and beverage processing requires “sanitary” (hygienic) stainless steel pipes and fittings — components designed to eliminate dead ends, crevices, and rough surfaces where bacteria can accumulate. Below are the most common types of sanitary stainless steel pipes and fittings used in F&B facilities.

1. Sanitary Stainless Steel Pipes

• Seamless Sanitary Stainless Steel Pipes: Ideal for high-pressure applications (e.g., pumping liquids) and environments where hygiene is critical (e.g., pharmaceutical-grade F&B). Seamless stainless steel pipes have no weld seams, eliminating potential crevices for contamination—one of the most reliable types of stainless steel pipes and fittings. Common sizes: ½” to 12” OD (Outer Diameter).

• Welded Sanitary Stainless Steel Pipes: A cost-effective alternative for low-to-medium pressure applications (e.g., gravity-fed systems, water lines). Welded stainless steel pipes are made from food-grade stainless steel sheets and welded into a tube, then polished to a smooth finish. They are suitable for most standard F&B processes and are widely used as stainless steel pipes and fittings.

Surface Finish Requirement: For F&B, sanitary stainless steel pipes — a key part of stainless steel pipes and fittings — must have a polished inner surface with an Ra (roughness average) value of ≤ 0.8 μm (micro meters). A smoother surface reduces bacterial adhesion and makes cleaning easier—critical for food-grade stainless steel components.

2. Sanitary Stainless Steel Fittings

Stainless steel fittings are critical for connecting stainless steel pipes, forming complete stainless steel pipes and fittings systems. They are used for changing direction and accessing the system for cleaning. All sanitary stainless steel fittings must be designed with no dead legs (sections where fluid can stagnate) and must be easy to disassemble—key requirements for F&B processing.

• Tri-Clamp Fittings: The most popular type of stainless steel fittings in F&B processing. Tri-Clamp Fittings use a clamp to connect stainless steel pipes, valves, or tanks, with a gasket to ensure a tight, hygienic seal. They are easy to disassemble for cleaning and are compatible with CIP systems, making them an essential part of stainless steel pipes and fittings systems. Common uses: connecting stainless steel pipes to tanks, pumps, or filters.

• Butt-Weld Fittings: Used for permanent connections where hygiene is paramount (e.g., high-pressure lines). Butt-Weld Fittings are welded directly to the stainless steel pipes, creating a smooth, seamless joint with no crevices—ideal for high-hygiene stainless steel pipes and fittings systems. Common types: elbows (90°, 45°), tees, reducers.

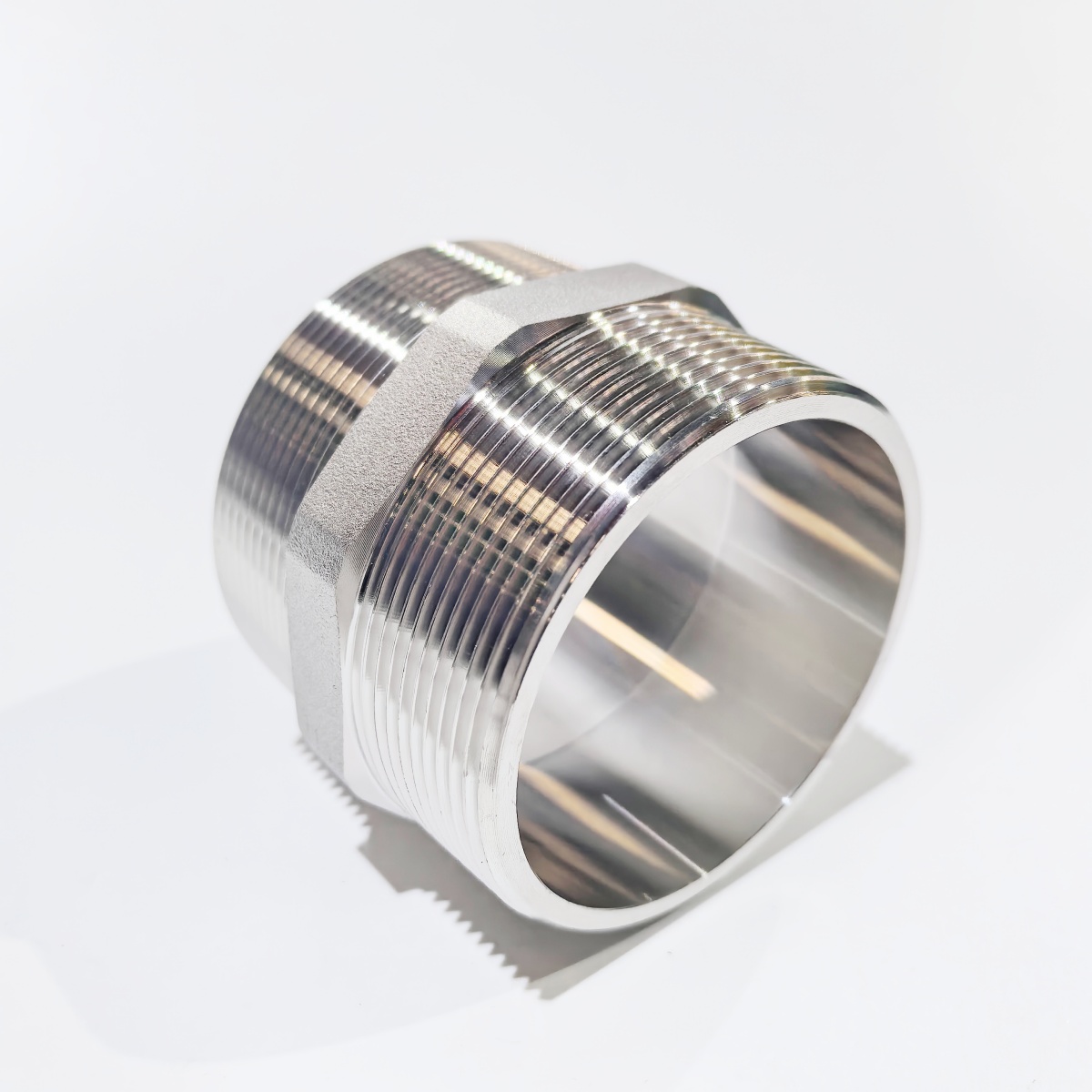

• Threaded Fittings: Suitable for low-pressure, non-critical applications (e.g., auxiliary water lines). Threaded Fittings must be food-grade stainless steel and have smooth threads to prevent bacterial buildup—an essential feature for F&B-related stainless steel pipes and fittings systems.

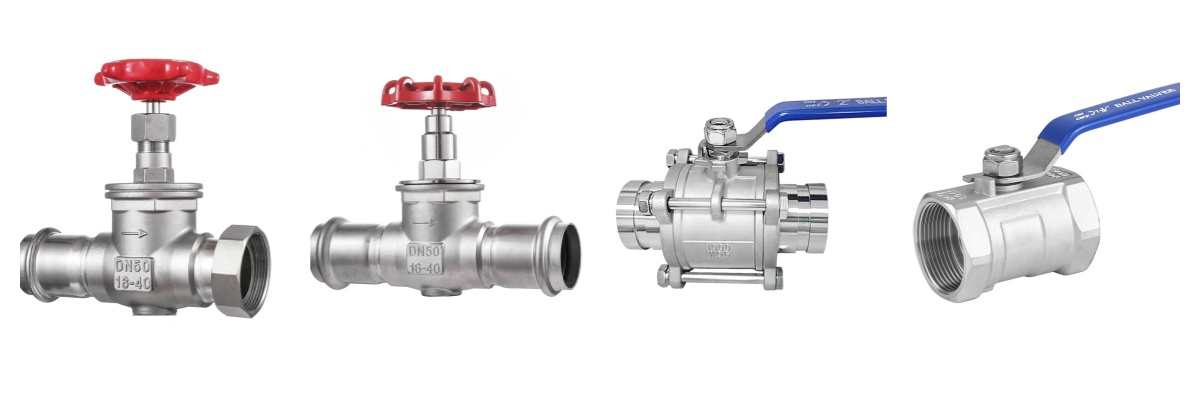

• Sanitary Stainless Steel Valves: Sanitary Stainless Steel Valves (e.g., ball valves, butterfly valves, check valves) control the flow of fluids in the stainless steel pipes and fittings system. They must be designed to be fully cleanable, with no internal cavities where fluid can stagnate—critical for maintaining hygiene in F&B processing.

Critical Standards & Certifications for F&B Stainless Steel Components

Guangzhou Mayer Certificates

Guangzhou Mayer Certificates

• FDA (U.S. Food and Drug Administration): The FDA regulates materials that come into contact with food and beverages in the United States. Food-grade stainless steel (304, 316L) used for stainless steel pipes and fittings must meet FDA 21 CFR Part 177.2600, which confirms it is non-toxic and does not leach harmful substances into food.

• 3A Sanitary Standards (U.S./Global): 3A standards are the gold standard for hygienic equipment in the F&B and dairy industries. 3A-certified stainless steel pipes and fittings are designed to be easily cleaned and sanitized, with no dead ends or crevices. This certification is especially important for dairy, beverage, and high-hygiene applications.

• CE (European Union): For clients in the EU, CE marking confirms that your stainless steel pipes and fittings meet the requirements of the EU’s Machinery Directive (2006/42/EC) and Food Contact Materials Regulation (EC) No 1935/2004. This allows your stainless steel pipes and fittings to be sold and used freely within the EU market.

• ASTM A270: An international standard (from the American Society for Testing and Materials) that specifies the requirements for seamless and welded sanitary stainless steel pipes — a key part of stainless steel pipes and fittings — for food and beverage processing. It covers material composition, surface finish, dimensions, and pressure ratings.

• DIN 11850 (Germany/EU): A German standard for sanitary stainless steel fittings — an important component of stainless steel pipes and fittings, specifying dimensions, materials, and hygiene requirements for fittings used in F&B and pharmaceutical processing. Clients in Germany and the EU often require compliance with DIN 11850 for stainless steel fittings.

Common Challenges in F&B Stainless Steel Pipe Systems (and How to Solve Them)

Foreign F&B clients often face specific challenges with their stainless steel pipes and fittings systems—and they look to manufacturers for solutions. Addressing these challenges in your article positions you as a knowledgeable partner for stainless steel pipes and fittings, not just a supplier.

• Challenge 1: Contamination Risks

Solution: Use 304/316L food-grade stainless steel for stainless steel pipes and fittings with a smooth Ra ≤ 0.8 μm finish. Choose sanitary stainless steel fittings with no dead legs (e.g., Tri-Clamp fittings) and ensure proper welding (butt-weld for seamless joints). Implement regular cleaning and sanitization protocols (CIP systems) for your stainless steel pipes and fittings system.

• Challenge 2: Corrosion in Acidic Environments

Solution: Upgrade to Grade 316L Stainless Steel for your stainless steel pipes and fittings, which contains molybdenum for enhanced corrosion resistance against acids and harsh sanitizers. Avoid using carbon steel components in contact with acidic F&B products alongside stainless steel pipes and fittings.

• Challenge 3: Leaks & Seal Failures

Solution: Use high-quality food-grade gaskets (e.g., EPDM, silicone) with Tri-Clamp Fittings — a type of stainless steel fittings. Ensure proper installation and torque of clamps for stainless steel fittings. Regularly inspect gaskets for wear and replace them promptly.

• Challenge 4: Compliance with Local Standards

Solution: Source from a manufacturer that provides FDA, 3A, and CE-certified stainless steel pipes and fittings. Ask for material test reports (MTRs) and compliance certificates to verify that stainless steel pipes and fittings meet your region’s standards.

Why Choose Us for Your Food & Beverage Stainless Steel Pipes & Fittings?

Guangzhou MAYER - Stainless Steel Tube and Fitting Manufacturer

As a professional manufacturer specializing in stainless steel pipes and fittings for the global F&B industry, we understand your unique needs. Here’s what sets us apart:

• Food-Grade Expertise: We only use 304 and 316L food-grade stainless steel to produce stainless steel pipes and fittings, with strict quality control to ensure Ra ≤ 0.8 μm surface finish and compliance with FDA, 3A, CE, ASTM A270, and DIN 11850 standards.

• Sanitary Design: All our stainless steel pipes and fittings are designed for F&B hygiene—no dead ends, crevices, or rough surfaces. We offer Tri-Clamp, butt-weld, and threaded stainless steel fittings to suit your stainless steel pipes and fittings system’s needs.

• Custom Solutions: We provide custom sizes, wall thicknesses, and finishes to match your specific processing requirements (e.g., high-pressure brewing systems, acidic juice processing) for stainless steel pipes and fittings.

• Full Compliance Documentation: We supply material test reports (MTRs), certification documents (FDA, 3A, CE), and quality inspection reports with every order of stainless steel pipes and fittings — so you can easily comply with local regulations.

• Global Export Experience: We have years of experience exporting stainless steel pipes and fittings to F&B clients worldwide (EU, US, Canada, Australia, Southeast Asia), with reliable lead times, secure packaging, and support for international shipping.

Guangzhou Mayer Certificates

Guangzhou Mayer Certificates

Get a Custom Quote for Your Food & Beverage Stainless Steel Needs

Whether you’re building a new F&B facility, upgrading your existing system, or need a reliable supplier for bulk orders of stainless steel pipes and fittings, we’re here to help. Contact us today with your specifications (material grade, size, quantity, and application), and we’ll provide a quick, accurate quote—along with free samples to verify quality of stainless steel pipes and fittings. Let’s partner to build a safe, hygienic, and compliant processing system for your food and beverage products. Inquire Now