The main differences between 304 and 316 stainless steel plates are as follows:

1. Composition Differences

304 Stainless Steel: Main components are iron, chromium (18%-20%), and nickel (8%-10%), without molybdenum.

316 Stainless Steel: Contains 2%-3% molybdenum compared to 304, with a slightly higher nickel content (10%-14%) and a chromium content of 16%-18%.

2. Corrosion Resistance

304 Stainless Steel: Strong resistance to atmospheric and freshwater corrosion, and can withstand general acid and alkali environments. However, its corrosion resistance is relatively weak in high-chlorine environments (such as seawater and chlorine-containing disinfectants) or under high-temperature and strong acid/alkali conditions.

316 Stainless Steel: Due to the presence of molybdenum, its resistance to chloride corrosion is significantly improved, especially in seawater, salt water, and high-concentration chloride ion environments. It also exhibits stronger resistance to reducing acids such as sulfuric acid and phosphoric acid.

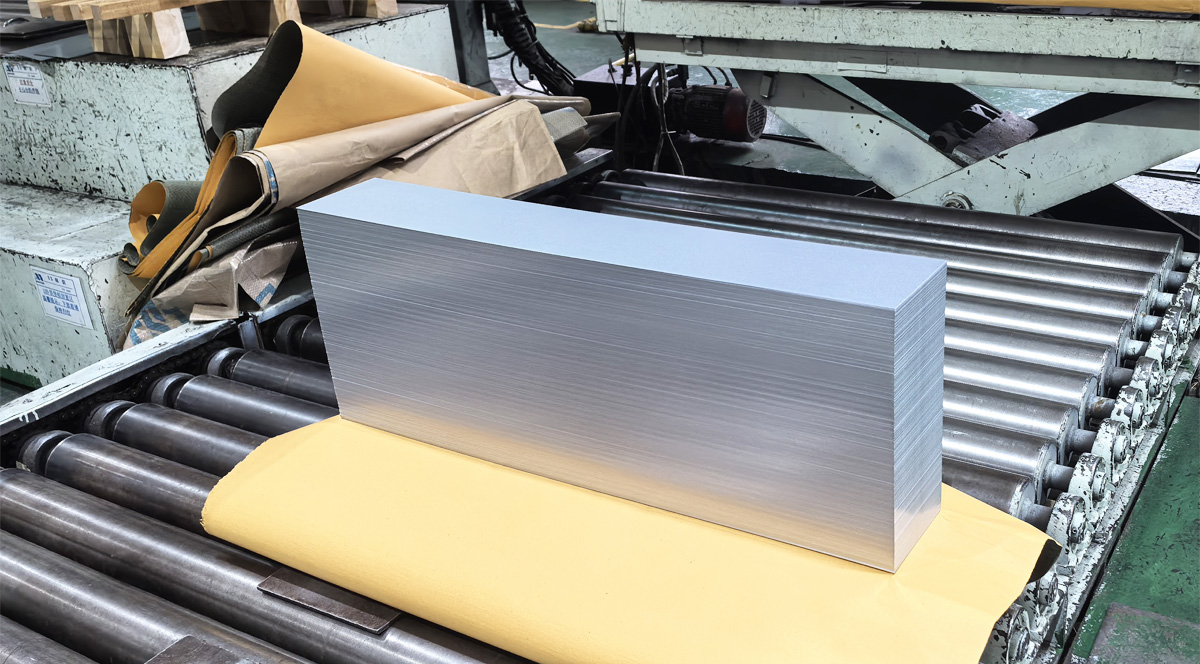

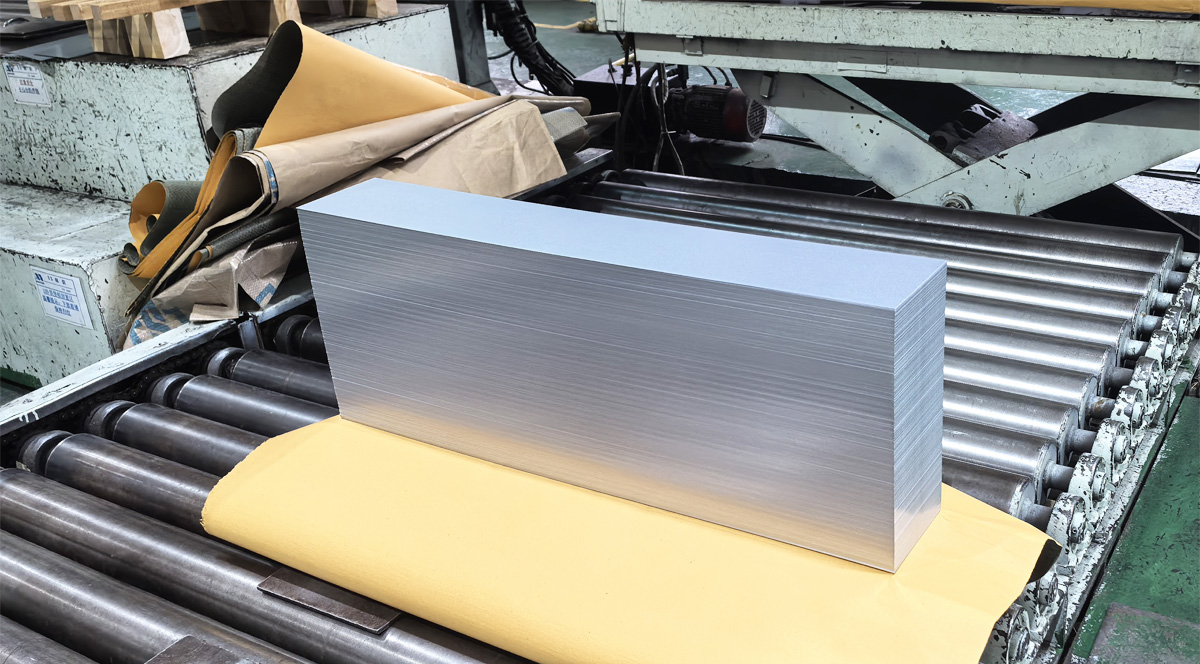

304/316L Stainless Steel Sheet

3. Heat Resistance

304 Stainless Steel: Can be used intermittently below 800℃, with continuous use generally not exceeding 870℃. It exhibits good oxidation resistance at high temperatures.

316 Stainless Steel: Offers superior high-temperature resistance, can be used intermittently below 1600℃ and continuously below 1700℃. It boasts better high-temperature strength and oxidation resistance.

4. Mechanical Properties

304 Stainless Steel: Tensile strength 520-720MPa, yield strength ≥205MPa, elongation ≥40%, hardness HB≤201. It possesses balanced comprehensive mechanical properties and good machinability.

316 Stainless Steel: Tensile strength around 560MPa, yield strength similar to 304, elongation similar, but slightly higher hardness (around HRB78), and better work hardening properties.

304/316L Stainless Steel Coil

5. Biocompatibility

304 Stainless Steel: Long-term contact may trigger skin allergic reactions in some individuals.

316 Stainless Steel: Offers better biocompatibility, with less skin irritation, and is commonly used in medical devices, implants, and other fields with high biocompatibility requirements.

6. Price

304 Stainless Steel: Lower cost and more affordable market price, it is the most widely used stainless steel grade.

316 Stainless Steel: Due to its molybdenum and nickel content, its production cost is higher, and its price is usually 20%-40% more expensive than 304.

Summary:

304 stainless steel offers high cost-effectiveness and is suitable for everyday household use, general industrial applications, and food contact scenarios; 316 stainless steel has better corrosion resistance and biocompatibility, making it suitable for special environments such as marine engineering, chemical engineering, and medical applications. The choice should be based on actual usage conditions and budget.

Guangzhou MAYER - Stainless Steel Pipe and Fitting Manufacturer