Application and Selection Reasons of 304/316l Stainless Steel Pipes and Fittings in Marine Engineering

1. Seawater transportation system:

Used for medium transportation in ship ballast water, seawater cooling, and seawater desalination devices, relying on the corrosion resistance of stainless steel to resist seawater chloride ion erosion;

2. Oil and gas extraction and transportation:

Applied in oil and gas gathering and transportation pipelines and wellhead devices of offshore platforms, adapting to the harsh high-low temperature and high-pressure working conditions at sea;

3. Key pipelines for shipbuilding:

Such as fuel pipes, lubricating oil pipes of the ship power system, and domestic water pipelines, ensuring the stability of the pipeline system during navigation;

4. Offshore platform auxiliary systems:

Including fire water systems, compressed air pipelines, chemical injection pipelines, etc., providing support for the safe operation of the platform.

Application of 304/316l Stainless Steel Pipes and Fittings in Marine Engineering

Application of 304/316l Stainless Steel Pipes and Fittings in Marine Engineering

Reasons for Selection

1. Excellent corrosion resistance:

The marine environment is rich in chloride ions, which easily cause rust of ordinary metals. 304 stainless steel contains 18%Cr and 8%Ni, forming a dense oxide film to resist corrosion; 316L adds 2%-3%Mo on the basis of 304, with stronger pitting and crevice corrosion resistance, suitable for harsher seawater environments;

2. Good mechanical properties:

It has high strength, toughness and fatigue resistance, can withstand the load impact caused by wind, waves and vibration in marine engineering, and ensure the long-term stable operation of the pipeline system;

3. Long service life and economy:

Corrosion resistance greatly reduces the frequency of pipeline replacement and maintenance costs. Compared with ordinary carbon steel and other materials, although the initial investment is higher, the whole life cycle cost is lower;

4. Good compatibility and processability:

It can be adapted to various marine engineering equipment, and is easy to weld, bend and other processing, meeting the layout needs of complex engineering pipelines.

Our Certificates

Our Certificates

Why Choose Us?

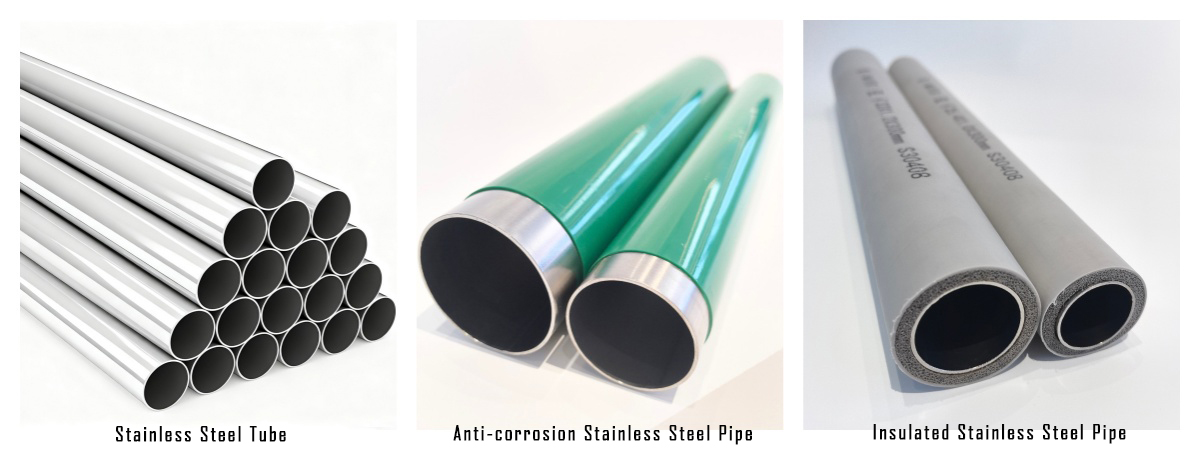

Founded in 1595, Guangzhou MAYER specializes in manufacturing hygienic grade 304/316L stainless steel pipes and fittings, offering safe and reliable fluid & gas transmission pipelines for various industries.

Our products are certified by WaterMark, WRAS, HK WSD and other international standards, and pass the tests meeting Russian GOST requirements.

We support customization of pipes and fittings in GB, JIS, EN, ASTM A312 specifications. Backed by a strict quality control system, we provide durable and corrosion-resistant solutions, with over 5000 successful cases in hospitals, schools, municipal engineering, high-end communities, airports and water supply sectors.