II. Applications in Engineering Projects

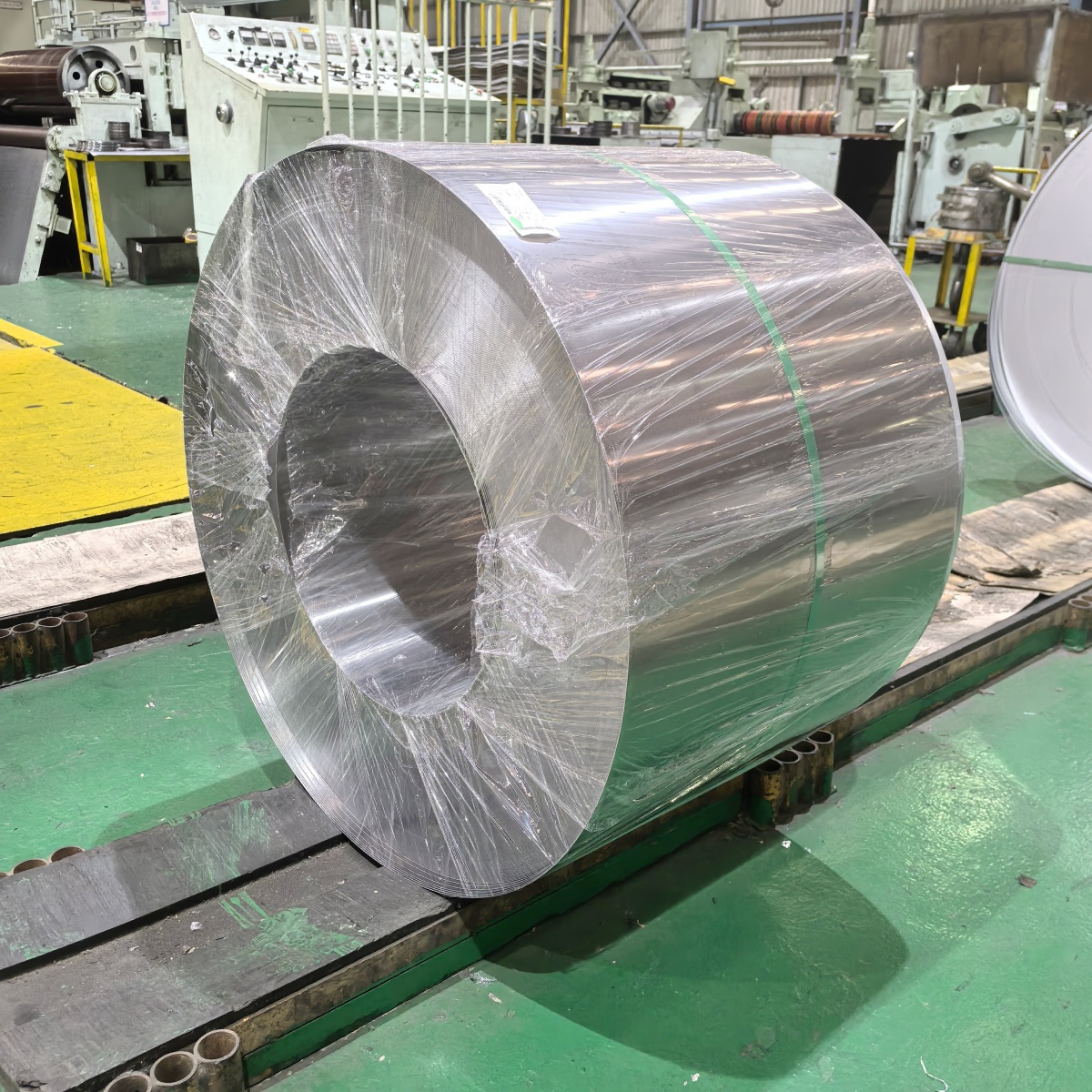

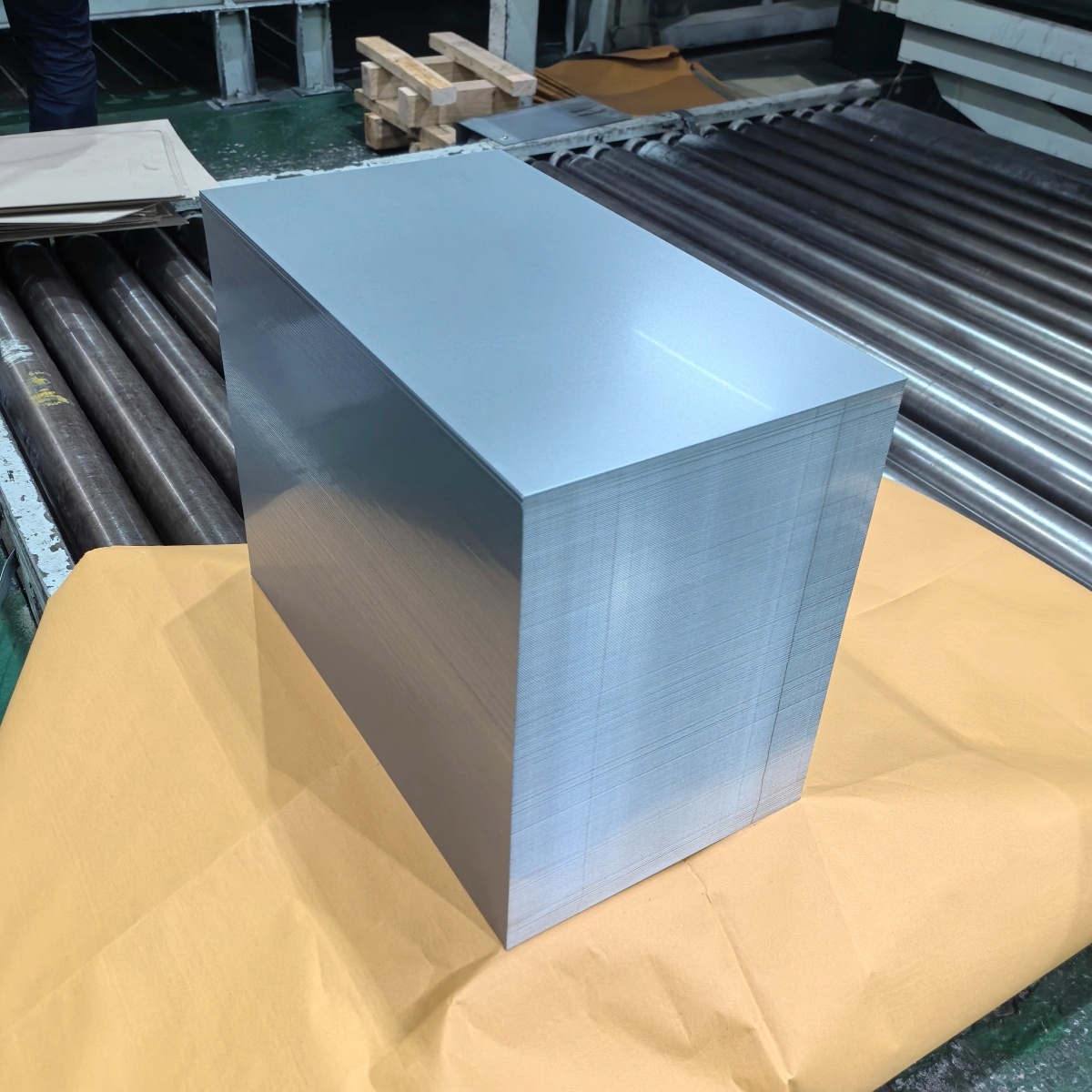

Cold Rolled 304 Stainless Steel Coil

It is widely used in building decoration panels, curtain wall materials, water supply and drainage pipe fittings, and small steel structural parts. It has high dimensional accuracy and good surface finish, can be directly used as an exposed decorative surface, and has excellent secondary processing performance such as bending and welding, adapting to the refined decoration of engineering and processing needs of small structural parts.

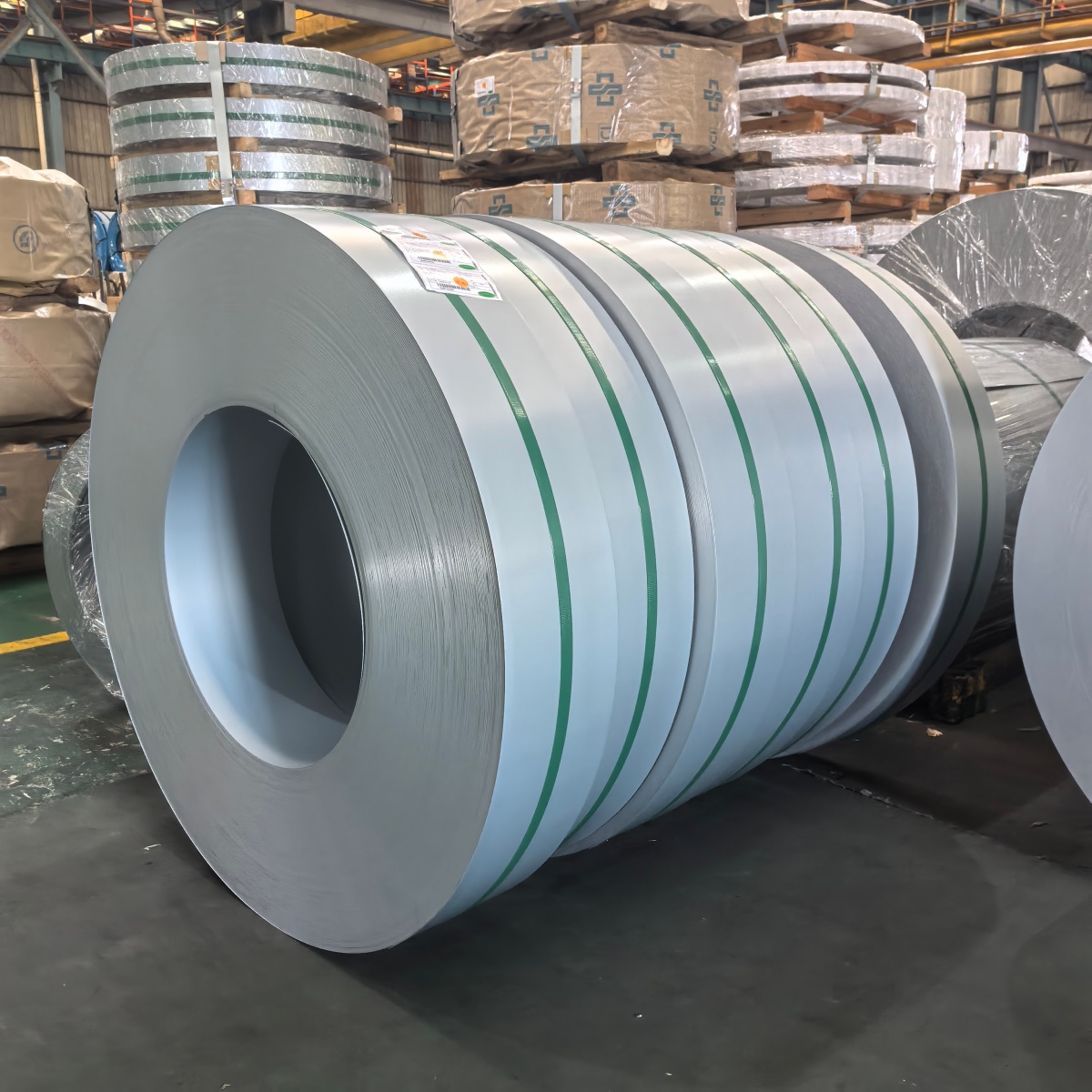

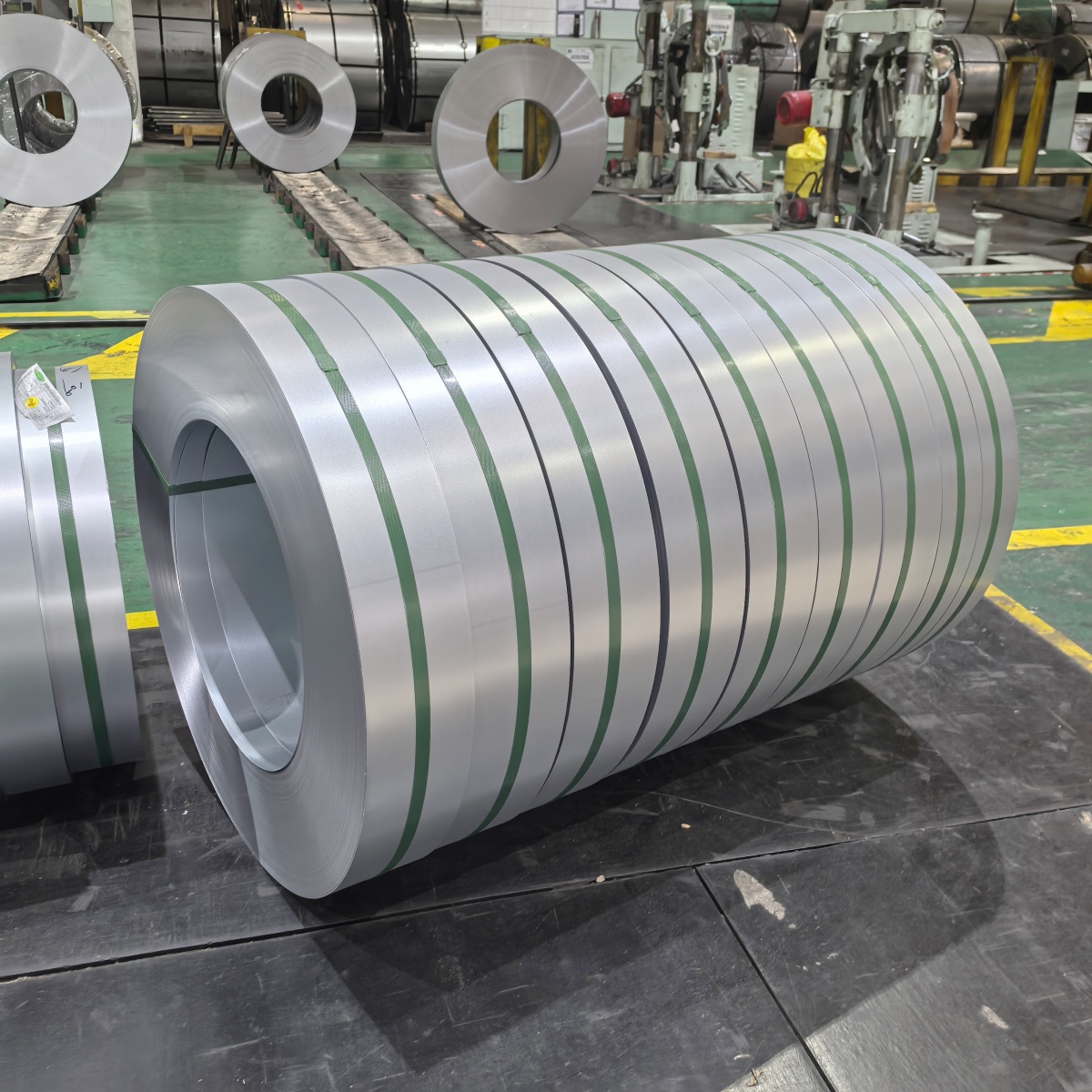

Hot Rolled 304 Stainless Steel Coil

It is mainly applied to the main building steel structure, bridge auxiliary components, industrial plant supports, and large municipal pipeline foundations. It has high yield strength and good impact resistance, can bear heavy engineering loads and complex outdoor working conditions. Large-specification coil plates can be directly cut and processed, adapting to the high-efficiency and low-cost needs of engineering mass construction, and is the preferred base material for engineering load-bearing/basic structures.

III. Core Reasons for Choosing Cold/Hot Rolled 304 Stainless Steel Coil

1. 304 stainless steel itself has excellent corrosion and oxidation resistance, adapting to complex working conditions such as humid/oily kitchens and outdoor/multi-medium engineering, not easy to rust and deform, with a long service life and reduced later maintenance costs;

2. Cold and hot rolled coils are adapted to scenarios on demand, balancing performance and cost: cold rolled coils have high precision and excellent appearance, meeting the high-quality requirements of kitchen contact parts and engineering decorative parts; hot rolled coils have high strength and cost performance, adapting to the structural load-bearing and basic construction needs of kitchens/engineering;

3. 304 stainless steel coils can be leveled, cut and bent on demand, with strong processing flexibility, matching the diversified customization needs of kitchen equipment and engineering projects. The material has strong versatility, making procurement and construction convenient.

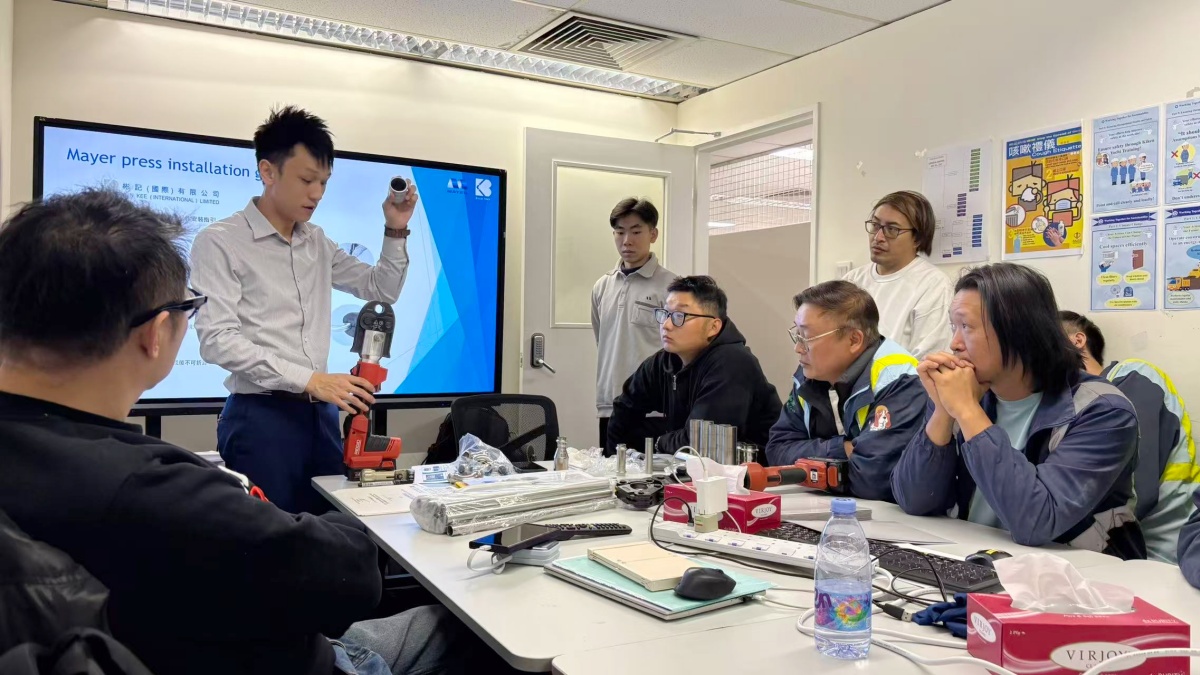

Why Choose MAYER?

Founded in 1995, Guangzhou Mayer Corp., Ltd. is a Sino-foreign joint venture listed on the Hong Kong Stock Exchange (Stock Code: 01116.HK) and a high-tech enterprise independently controlling the entire production process from steel coil cutting to finished stainless steel pipes and fittings.

Our core products include stainless steel coils/plates, stainless steel pipes and pipe fittings. All products have passed international standard certifications such as WaterMark, WRAS and HK WSD, and successfully passed tests meeting Russian GOST requirements. Backed by a strict quality control system, we provide durable, corrosion-resistant, long-service-life and cost-effective product solutions for global buyers, and have accumulated more than 5,000 successful application cases in hospitals, schools, municipal engineering, high-end residential communities, airports, water utilities and other fields.

Mayer actively participates in the formulation of national standards, holds 52 invention and utility model patents, and is also the Guangdong Provincial Engineering Technology Research Center for Stainless Steel Piping. Since 2005, the company has been awarded the title of "Contract-abiding and Credit-worthy Enterprise" for 16 consecutive years, winning recognition from global customers with reliable strength and credibility.