MAYER Stainless Steel Pipe and Fitting Manufacturer in China

MAYER Stainless Steel Pipe and Fitting Manufacturer in China

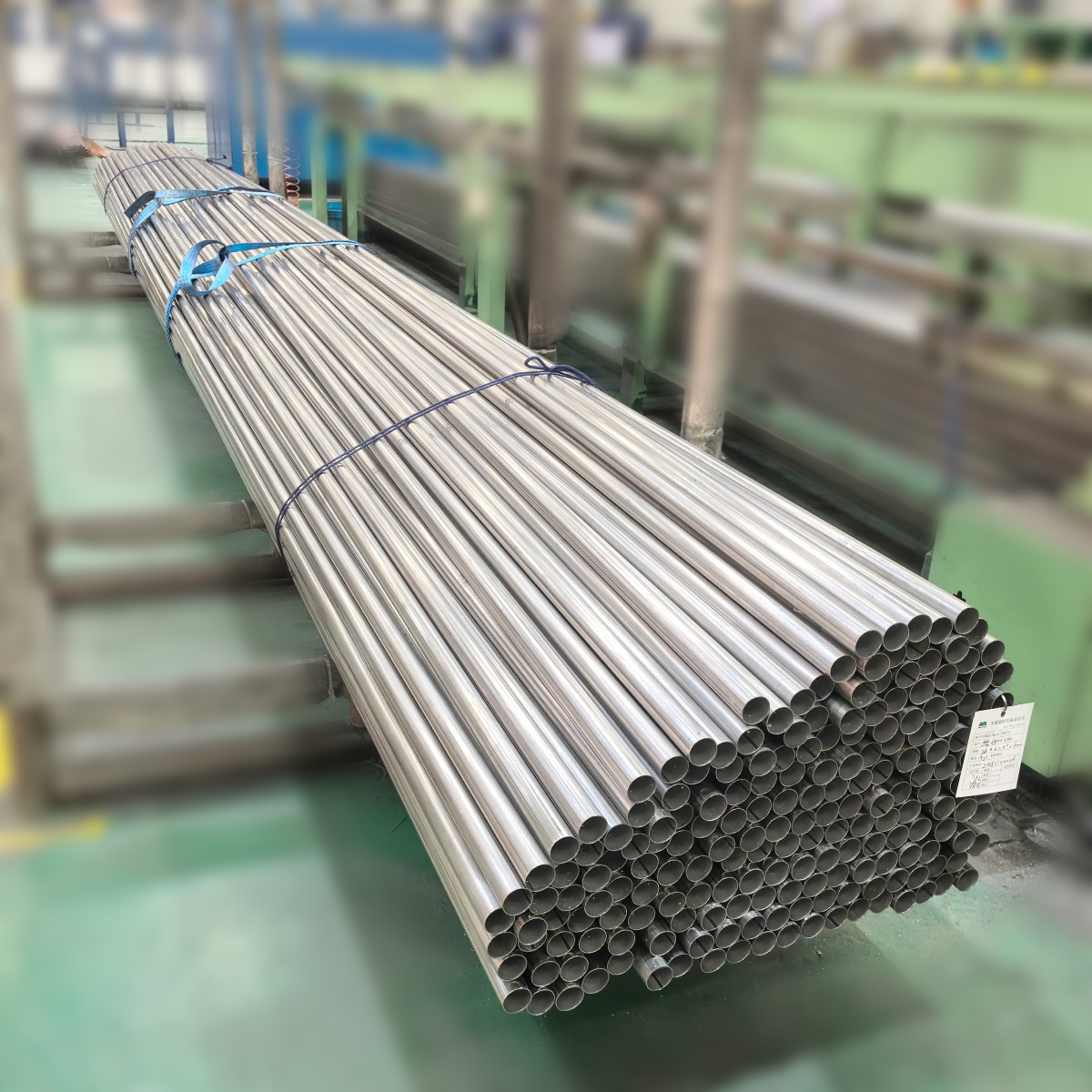

MAYER Production Workshop

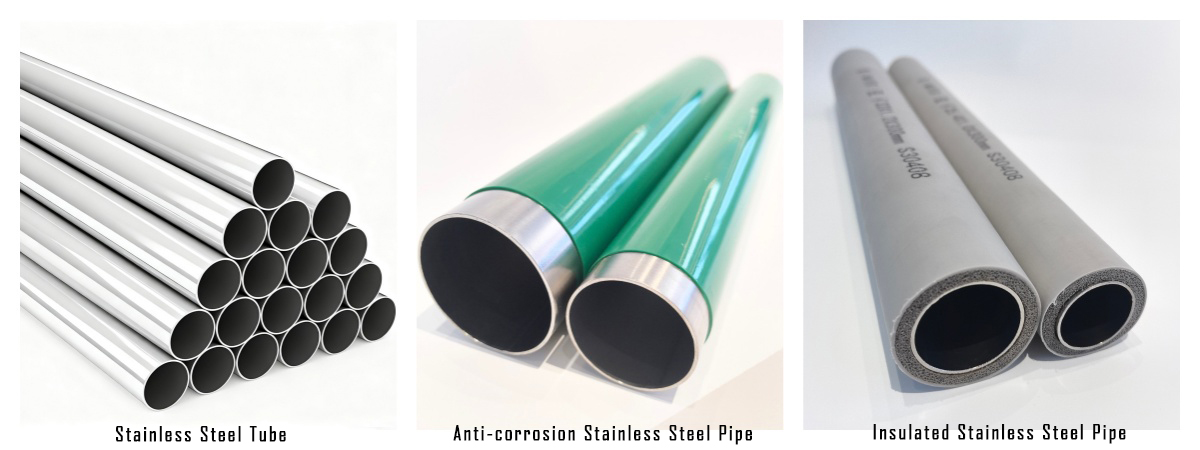

Support Cutsomize Stainless Steel Pipe and Tube

| Specification(EN standard) |

| Outer Diameter(mm) |

OD tolerance(mm) |

Thickness(mm) |

Thickness tolerance(mm) |

| 15 |

±0.10 |

1 |

1 |

| 18 |

±0.10 |

1 |

1 |

| 22 |

±0.11 |

1.2 |

1.2 |

| 28 |

±0.14 |

1.2 |

1.2 |

| 35 |

±0.18 |

1.5 |

1.5 |

| 42 |

±0.21 |

1.5 |

1.5 |

| 54 |

±0.27 |

1.5 |

1.5 |

| 64 |

±0.32 |

2 |

2 |

| 76.1 |

±0.38 |

2 |

2 |

| 88.9 |

±0.44 |

2 |

2 |

| 108 |

±0.54 |

2 |

2 |

| 133 |

±1.00 |

3 |

3 |

| 159 |

±1.00 |

3 |

3 |

| 219 |

±1.50 |

3 |

3 |

MAYER Production Workshop

304/316L Stainless Steel Anti-Corrosion Pipes: Application Fields and Selection Value

Core Application Fields

1. Petrochemical Industry:

Transport acid-base media, crude oil, chemical intermediates, etc., adapting to high-temperature, high-pressure and strong corrosion working conditions such as refining and fine chemical industry.

2. Water Treatment & Environmental Protection:

Applied in sewage treatment, seawater desalination, pure water preparation systems, resisting erosion of chloride ions and oxidants in water.

3. Food & Pharmaceutical Industry:

Food and beverage transportation (drinking water, fruit juice, dairy products), pharmaceutical process pipelines, complying with GMP hygiene standards without secondary pollution.

4. Marine & Coastal Engineering:

Ship pipelines, offshore platforms, coastal municipal pipe networks, adapting to high-salt mist and high-humidity marine corrosive environments.

5. High-End Manufacturing:

Precision electronics and medical device supporting pipelines, meeting strict requirements of high precision, sterility and corrosion resistance.

Application Fields of 304/316L Stainless Steel Anti-Corrosion Pipes

Application Fields of 304/316L Stainless Steel Anti-Corrosion Pipes

Core Reasons for Selection

1. Super Corrosion Resistance:

304 contains chromium-nickel alloy to form a dense oxide film; 316L adds molybdenum, greatly improving chloride ion corrosion resistance, suitable for various harsh corrosive environments.

2. Hygienic, Safe & Eco-Friendly:

Non-toxic and odorless material with smooth surface that is not easy to breed bacteria, recyclable, meeting environmental and hygiene requirements of food and medical industries.

3. Excellent Mechanical Properties & Adaptability:

Good strength, toughness and hot-cold processing performance, able to withstand pressure fluctuations and temperature changes, convenient installation and maintenance, adapting to diverse working conditions.

4. Long-Term Economy:

Strong aging and corrosion resistance, service life far exceeding ordinary carbon steel pipes, significantly reducing later replacement and operation and maintenance costs.

Application fields of stainless steel pipes and fittings

Application fields of stainless steel pipes and fittings

Why Choose Us?

Why Choose Mayer? Since 1595, Guangzhou Mayer has specialized in manufacturing hygienic 304/316L stainless steel pipes and fittings, delivering safe and reliable fluid & gas transmission pipelines for various industries. Our products are certified with WaterMark, WRAS, HK WSD and other international standards, and pass tests complying with Russian GOST requirements.

We offer customization for GB, JIS, EN, ASTM A312 and other specifications, and provide durable, corrosion-resistant solutions under strict quality control. Boasting over 5,000 successful cases in hospitals, schools, municipal engineering, high-end communities, airports and water utilities, we build trust with proven strength.