| Pipe | Model | Describe | Cutting ability (mm) | Weight (kg) | Package |

| Metal tube cutting | 151 | Rapid feed cutter | 6-42 | 0.56 | 6 |

| 152 | 6-66 | 0.92 | 1 | ||

| 153 | 32-90 | 0.92 | 1 | ||

| 154 | 48 -116 | 1.72 | 1 | ||

| 156 | 100-170 | 2.23 | 1 | ||

| Plastic pipe cutting | 151-P | Rapid feed cutter | 10-40 | 0.56 | 1 |

| 152-P | 10-63 | 0.92 | 1 | ||

| 153-P | 25-75 | 0.92 | 1 | ||

| 154-P | 50-110 | 1.72 | 1 | ||

| 154-EP | 50-110 | 1.72 | 1 | ||

| 156-P | 110-160 | 2.23 | 1 | ||

| 156-EP | 110-160 | 2.23 | 1 | ||

| Aluminum plastic composite pipe cutting | 151-ML | Rapid feed cutter | 3-40 | 0.5 | 1 |

| Stainless steel corrugated pipe cutting | 151CSST | Stainless steel corrugated pipe cutter | 10-25 | 0.5 | 6 |

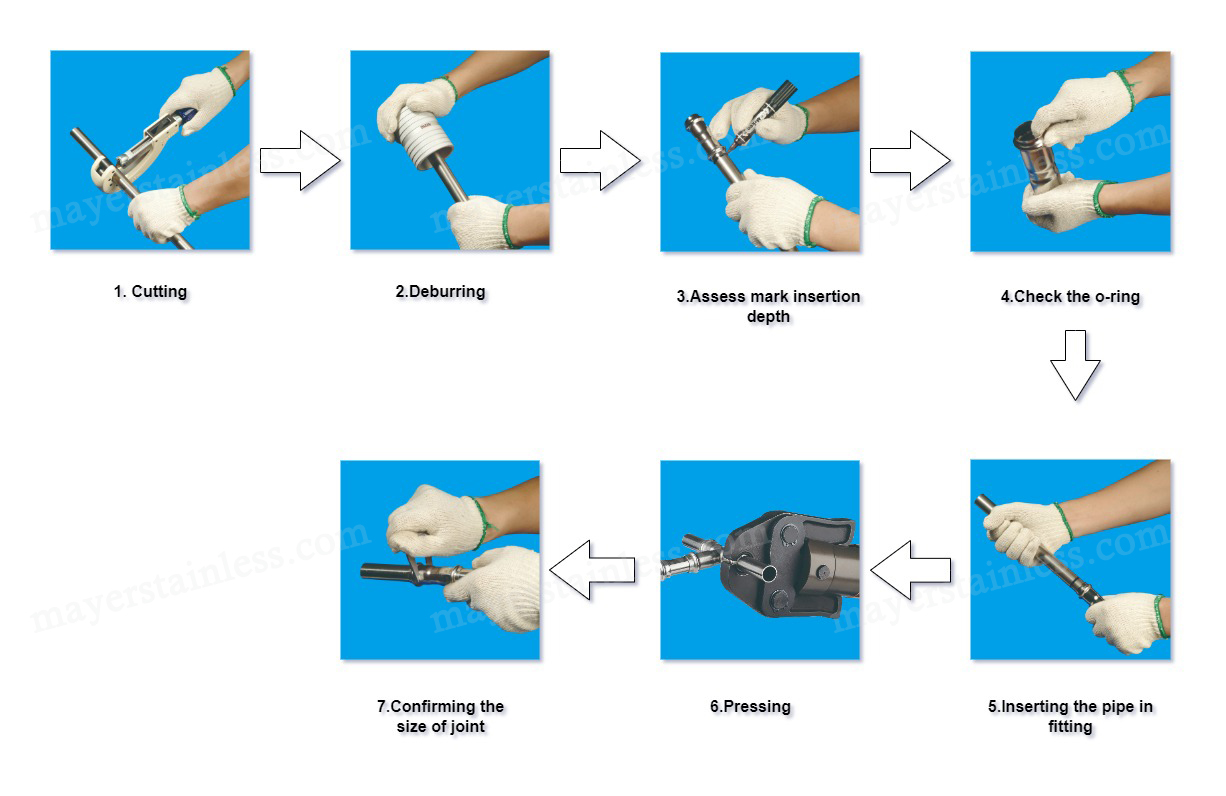

Installation Process

1. Cutting:

Confirm the pipe length needed, and cut it with approved burr-free cutters.

Oxy-acetylene torches and abrasive cut-off wheels are not suitable.

2.Deburring

Carefully deburr all pipe cuts inside and outside with a deburrer. Remove any cutting residue thoroughly.

3.Assess mark insertion depth

Mark the pipe with afine-pointfelt pen whereitmeets the fittingforverification offullinsertion.

4.Check the o-ring

Check the positioning of the o-ring, and lubricate the o-ring with wateror talc to ease insertion ofthe pipe if necessary. Make sure that the pipe andfttings are clean,no oil and sundries are covered on it.

5.Inserting the pipe in fitting

The pipe is inserted in the fitting with a slight rotating motion until it hits the stop. Check the pipe against the felt pen mark to ensure completeinsertion. And the insertion should not be forced at an angle, which will easilycause damage to the o-ring.

6.Pressing

Position the jaw over the fitting, creating a perfect fit with the internal channel of the jaw around the toroidal seat of the fitting. Make sure that the jaws are perpendicular to the joint, and squeeze the trigger to initiate the press cycle, holding it down for the full duration of press cycle.

7.Confirming the size of joint

Confirm the size ofjoint by measuring the section dimension with a special gauge.

Hydraulic tools for crimping stainless steel pipes and fittings

Crimping sit

Copyright © 2025 Guangzhou Mayer Corp., Ltd | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist