E-mail : info@mayer.cn

E-mail : info@mayer.cn

2025-09-17

Stainless steel pipes are widely used in building construction due to their excellent corrosion resistance, high strength, good ductility, aesthetic appeal, and long service life. Below is a detailed explanation of their specific roles and important considerations.

Specific Roles of Stainless Steel Pipes in Buildings

Depending on their purpose and performance, stainless steel pipes primarily serve the following roles:

1. Structural Components

。Role: Serving as primary or secondary load-bearing supports.

Stainless steel pipe for railing decoration

。Applications:

* Support systems for glass curtain walls: As mullions (vertical rails) and beams to support large glass panels, enabling the transparent appearance of modern architecture.

* Railings and handrails: For balconies, staircases, corridors, and rooftops, combining safety and aesthetics.

* Roof truss structures: For large-span buildings such as airports, stadiums, and exhibition centers.

* Decorative structures: As frameworks for canopies, sunshades, and façade grilles.

2. Fluid Transport Pipelines

。Role: Transporting potable water, direct drinking water, gas, firefighting water, etc.

Stainless Steel Tube for Construction

Food Grade Stainless Steel Pipe for Drink Water

。Applications:

* High-quality water supply systems: Especially for direct drinking water systems, ensuring no secondary pollution or leaching of harmful substances.

* Fire sprinkler systems: Their high strength and corrosion resistance ensure reliability in critical situations.

* Central air conditioning systems: For transporting chilled and cooling water.

* Gas pipelines: For indoor gas transportation.

3. Electrical and Communication Conduits

。Role: Protecting wires and cables from physical damage, moisture, and fire.

。Applications:

* Embedded in concrete or exposed in ceilings as conduits for power, control, and communication cables. Their mechanical and fire resistance properties are far superior to plastic pipes.

To ensure optimal performance and extended service life, the following key points must be noted:

1. Material Selection is Critical

。Grade selection: Different environments require different stainless steel grades.

* 304 (06Cr19Ni10): Most common, suitable for most indoor and general atmospheric environments (e.g., railings, decorative pipes, indoor water pipes).

* 316 (06Cr17Ni12Mo2): Contains molybdenum (Mo), offering better resistance to chloride corrosion. Ideal for coastal areas, chemical plants, de-icing salt environments, or regions with high chloride content in water.

* 2205 Duplex stainless steel: Extremely high strength and excellent resistance to chloride stress corrosion cracking. Used in harsher environments (e.g., offshore structures, chemical environments).

。Surface finish: Selected based on aesthetic and anti-fouling requirements.

* Brushed (HL): Common, resistant to minor scratches, easy to maintain.

* Mirror (BA/8K): Highly decorative but prone to fingerprints and scratches. Mostly used for indoor decoration.

* Passivation treatment: Critical! After processing and installation, passivate the pipe surface to remove iron contamination and enhance the protective chromium oxide layer.

2. Design and Installation Considerations

。Avoid galvanic corrosion:

* Never allow direct contact with other metals like carbon steel (e.g., rebar, angle iron). If connection is necessary, use insulating gaskets (e.g., nylon, rubber, Teflon) to isolate them and prevent corrosion due to potential differences.

。Prevent crevice corrosion:

* Avoid designing narrow gaps in connection points (e.g., bolted connections are more prone to gaps than welding). Gaps can trap liquids and cause oxygen depletion, accelerating corrosion.

。Welding techniques:

* Use welding rods/wires specifically for stainless steel.

* Prefer argon arc welding with backside argon protection to prevent oxidation of the weld seam, which affects corrosion resistance.

* After welding, perform acid pickling and passivation on the weld and heat-affected zones to restore corrosion resistance.

。Support and fixation:

* Use supports and clamps made of stainless steel (preferably the same or higher grade than the pipe) to avoid galvanic corrosion.

* Ensure proper spacing between fixings to prevent excessive deflection due to self-weight or fluid dynamics.

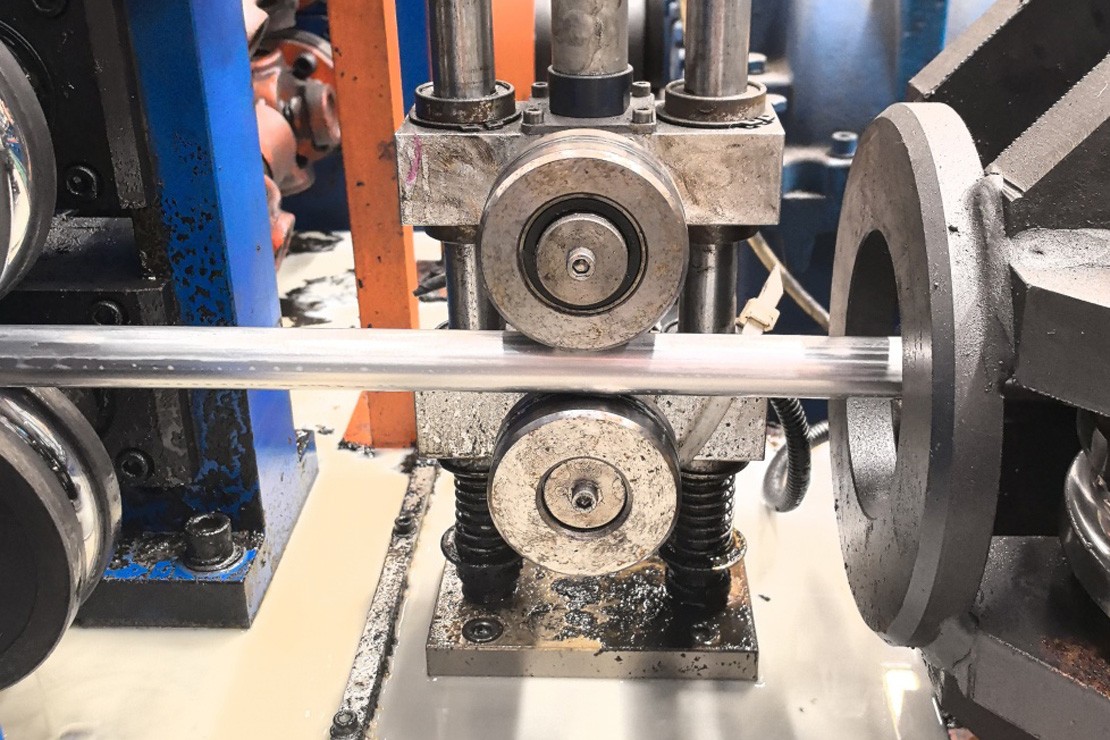

Mayer stainless steel pipes in production

3. Usage and Maintenance

。Cleaning:

* Regularly clean the surface with water and neutral soap to remove dust and dirt.

* Avoid cleaners containing chlorine (e.g., bleach), hydrochloric acid, or abrasive cleaners, as these can damage the passivation layer.

。Inspection:

* Periodically check for signs of abnormal corrosion, scratches, or damage, especially at welds and connection points.

。External environment:

* While stainless steel is corrosion-resistant, it is not entirely rust-proof. In harsh environments (e.g., industrial pollution, coastal salt spray), regular maintenance and cleaning are still necessary.

Mayer - Stianless Steel Pipe and Fitting Manufacturer

Conclusion:

Stainless steel pipes represent a perfect combination of performance, aesthetics, and longevity in modern buildings. To ensure they fulfill their intended roles, it is essential to:

* Select materials scientifically: Choose the correct grade and surface treatment based on the environment.

* Execute precise installation: Strictly adhere to installation standards, particularly avoiding contact with other metals and performing post-weld treatments.

* Implement proper maintenance: Conduct regular and correct cleaning and inspections.

By following these guidelines, stainless steel pipes can provide safe, reliable, long-lasting, and aesthetically pleasing service to buildings.